Selecting the right nut grade is essential for ensuring strength, safety, and long-term performance in any mechanical, structural, or industrial application. Although nuts appear simple, every nut is manufactured to a specific strength class, material grade, and international standard—all of which determine how well it performs under load and how safely it pairs with a bolt.

This guide provides a clear overview of the Grades of Nuts, how strength classes work, and how global standards such as ISO, DIN, ANSI/ASME, SAE, GB, and JIS classify them.

What Are Nut Grades?

A nut grade defines the mechanical properties of a nut, including its proof load, tensile strength, and hardness. These values ensure that the nut can safely match the bolt grade it is paired with.

Nut grades generally fall into three main categories:

- Metric nut strength classes (ISO / DIN standards)

- Imperial nut grades (ANSI / SAE standards)

- Stainless steel and specialty alloy nut grades

Despite using different numbering systems, all standards serve one purpose:

to ensure the nut provides equal or greater strength than the bolt in the assembly.

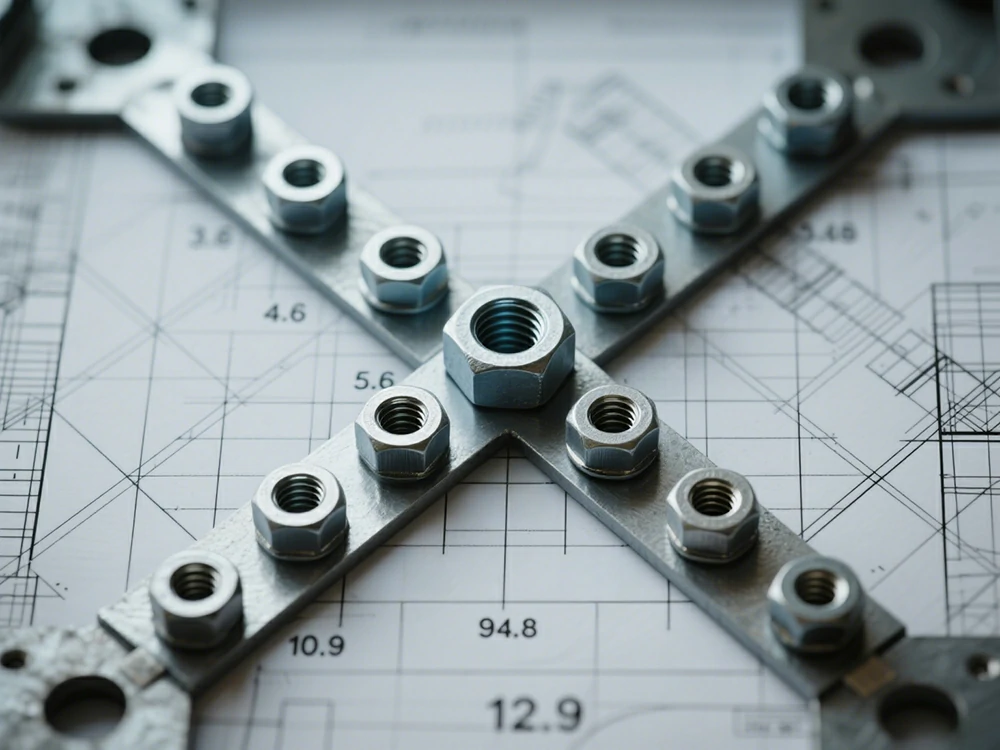

1. Metric Nut Strength Classes (ISO / DIN Standards)

Metric nuts primarily follow ISO 898-2, DIN 934, and other related standards.

Their grade is shown as a single number, such as 4, 6, 8, 10, or 12.

Common Metric Nut Classes

- Class 4

- Class 5

- Class 6

- Class 8

- Class 10

- Class 12

What the Numbers Mean

The class number indicates the proof load strength – the maximum stress a nut can withstand before permanent deformation.

Metric Nut Strength Classes Explained

|

Strength Class |

Typical Use |

Proof Load (MPa) |

Matches Bolt Grades |

|

4 |

Light-duty, low stress |

~225 MPa |

4.6 bolts |

|

5 |

Medium-duty |

~310 MPa |

5.8 bolts |

|

6 |

General construction |

~380 MPa |

6.8 bolts |

|

8 |

Machinery, automotive |

~600 MPa |

8.8 bolts |

|

10 |

Heavy machinery |

~830 MPa |

10.9 bolts |

|

12 |

High-stress applications |

~970 MPa |

12.9 bolts |

Most Common Industrial Choices

- Class 8 nuts – everyday machinery and automotive

- Class 10 nuts – heavy-duty structural assemblies

- Class 12 nuts – precision or extremely high-stress joints

2. Imperial Nut Grades (ANSI/ASME & SAE Standards)

Inch-series fasteners follow SAE J995, ASME B18.2.2, and ASTM A563/A194 for heavy hex nuts.

Common Imperial Nut Grades

- Grade 2

- Grade 5

- Grade 8

- Grade 9 (special high-strength)

Imperial Nut Grades Overview

|

Grade |

Material |

Strength |

Common Use |

|

Grade 2 |

Low-carbon steel |

Low |

Household hardware, light-duty |

|

Grade 5 |

Medium carbon steel, quenched & tempered |

Medium |

Machinery, automotive |

|

Grade 8 |

Alloy steel, quenched & tempered |

High |

Heavy equipment, load-bearing |

|

Grade 9 |

Boron/alloy steel |

Very High |

High-vibration and extreme loads |

Key Rule:

A nut must match or exceed the grade of the bolt.

3. Stainless Steel Nut Grades

Stainless nuts are classified differently from carbon steel fasteners. They use a combination of steel type and strength class.

Common Stainless Nut Grades

- A2-70 (304 stainless)

- A4-70 (316 stainless)

- A4-80 (316 stainless, work-hardened)

How to Read Stainless Nut Grades

Example: A4-80

- A4 = 316 stainless steel (excellent corrosion resistance)

- 80 = 800 MPa tensile strength

|

Grade |

Tensile Strength |

Corrosion Resistance |

Typical Use |

|

A2-70 |

Medium |

Good |

Outdoor general use |

|

A4-70 |

Medium |

Excellent |

Marine, chemical, food processing |

|

A4-80 |

High |

Excellent |

Heavy-load stainless steel applications |

4. International Nut Standards

ISO Standards

- ISO 898-2 – Mechanical properties

- ISO 4032 – Hex nuts (style 1)

- ISO 4033 – Hex nuts (style 2)

DIN Standards (Germany)

- DIN 934 – Hex nuts

- DIN 985 – Nylon insert lock nuts

- DIN 439 – Thin / jam nuts

ASME/SAE Standards (USA)

- ASME B18.2.2 – Hex nuts

- SAE J995 – Mechanical property requirements

GB Standards (China)

- GB/T 6170 – Hex nuts

- GB/T 3098.2 – Mechanical properties

- GB/T 6175 – High-strength nuts

JIS Standards (Japan)

How to Choose the Right Nut Grade

1. Match the Nut to the Bolt Grade

- 8.8 bolt → Class 8 nut

- 10.9 bolt → Class 10 nut

- 12.9 bolt → Class 12 nut

- Grade 5 bolt → Grade 5 nut

- Grade 8 bolt → Grade 8 nut

2. Consider the Environment

- Marine / chemical → A4 stainless

- Outdoor exposed → A2 stainless

- High vibration → locking nuts

3. Consider Mechanical Requirements

- Heavy machinery → Class 10 / Grade 8

- Light-duty → Class 4 / Grade 2

4. Add a Safety Margin

Professional engineers often choose a nut one grade higher than necessary for additional reliability.

Why Nut Grades Matter

Using the wrong nut grade may result in:

- Thread stripping

- Nut cracking

- Bolt failure

- Reduced fatigue life

- Mechanical accidents

Correctly matched fasteners ensure:

- Stronger clamping force

- Higher reliability

- Longer service life

- Compliance with international fastener standards

Conclusion

Understanding the Grades of Nuts and how different standards classify strength levels is essential for safe and reliable fastening. Whether you’re working in construction, automotive, machinery, or heavy industry, selecting the correct nut grade ensures proper performance, safety, and long-term durability.

Looking for reliable high-strength nuts, heavy hex nuts, or stainless steel fasteners?

Tianqi provides certified, precision-manufactured nuts that meet ISO, DIN, ANSI/ASME, and GB standards.

Contact Tianqi today for custom fastener solutions and bulk pricing.