Description

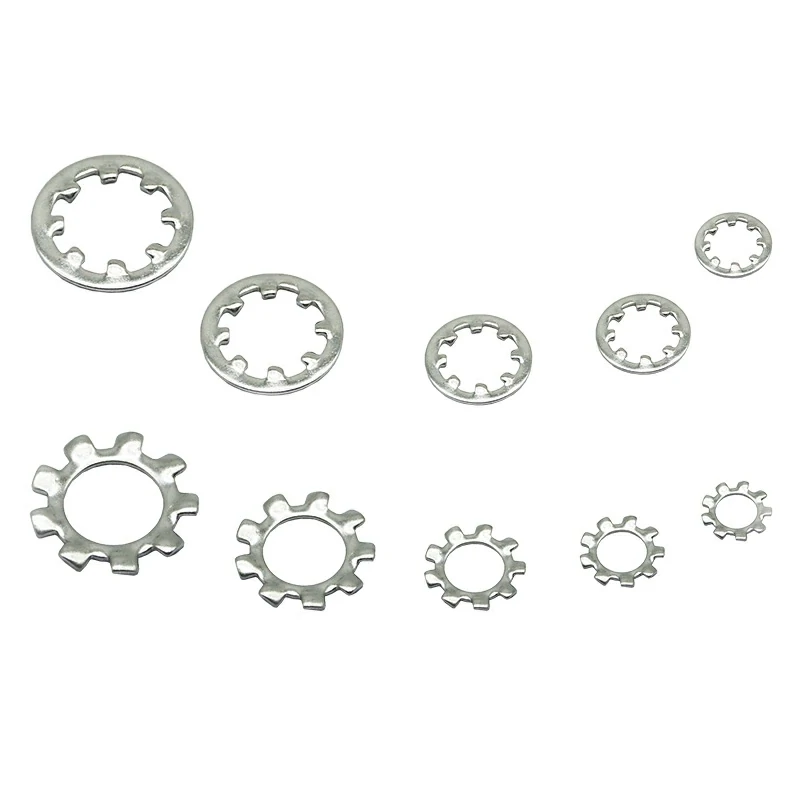

The 304 Stainless Steel Internal Tooth Lock Washer and an External Tooth Lock Washer are both types of lock washers designed to prevent bolted joints from loosening due to vibration or expansion/contraction. Both internal and external tooth lock washers are essential for maintaining the integrity of fastened joints, ensuring they remain secure even in high-vibration conditions or extreme environmental settings. Both types of tooth lock washers leverage their serrated teeth to mechanically lock a fastener in place, with the choice between internal and external depending on the specific fastener size, aesthetic requirements, and the desired level of locking force. Manufactured from durable 304 Stainless Steel, this washer offers excellent corrosion resistance and high wear resistance without sacrificing hardness. Conforming to the Chinese National Standard GB861.1 (Internal Teeth), the external teeth (GB862.1) version is also available for wider contact.

Features & Benefits

- Mechanical Locking: Creates a physical, multi-point lock against the mating surfaces, providing firm locking against rotation caused by vibration.

- 304 Stainless Steel: Offers exceptional corrosion resistance and oxidation resistance, preventing rust in humid or challenging environments.

- Load Distribution & Anti-Marring: Distributes the clamping force evenly while the teeth maintain the mechanical lock, protecting the mating surface from being severely marred by the fastener itself.

- High Hardness & Structural Stability: Maintains shape under pressure with no deformation, ensuring a reliable fit with bolts and screws.

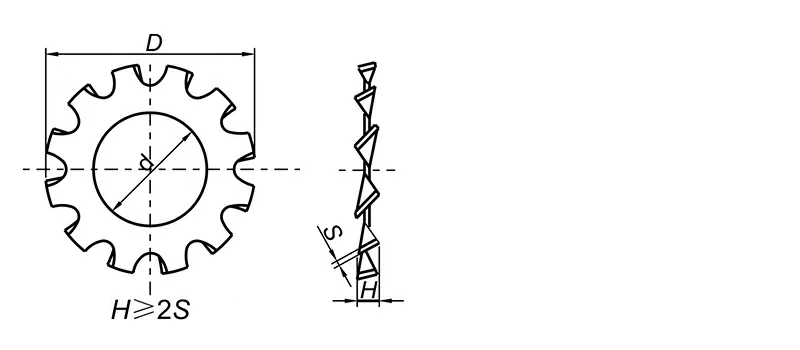

Specification

|

Specification (large diameter of thread) |

d |

D |

s |

Number of teeth |

The weight of every 1000 steel products is ≈kg |

||

|

min |

max |

min |

max |

min |

|||

|

2 |

2.2 |

2.45 |

4.2 |

4.5 |

0.3 |

6 |

0.2 |

|

2.5 |

2.7 |

2.95 |

5.2 |

5.5 |

0.3 |

6 |

0.3 |

|

3 |

3.2 |

3.5 |

5.7 |

6 |

0.4 |

6 |

0.4 |

|

4 |

4.3 |

4.6 |

7.64 |

8 |

0.5 |

8 |

0.10 |

|

5 |

5.3 |

5.6 |

9.64 |

10 |

0.6 |

8 |

0.18 |

|

6 |

6.4 |

6.76 |

10.6 |

11 |

0.6 |

8 |

0.21 |

|

8 |

8.4 |

8.76 |

14.6 |

15 |

0.8 |

8 |

0.47 |

|

10 |

10.5 |

10.93 |

17.6 |

18 |

1 |

9 |

0.80 |

|

12 |

12.5 |

12.93 |

20 |

20.5 |

1 |

10 |

1.12 |

|

14 |

14.5 |

14.93 |

23.5 |

24 |

1.2 |

10 |

1.69 |

|

16 |

16.5 |

16.93 |

25.5 |

26 |

1.2 |

12 |

2.10 |

|

18 |

19 |

19.52 |

29.5 |

30 |

1.5 |

12 |

3.14 |

|

20 |

21 |

21.52 |

32.4 |

33 |

1.5 |

12 |

3.80 |

|

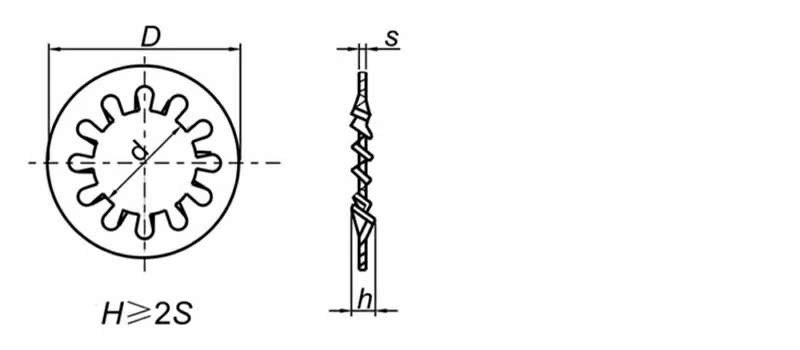

Specification (large diameter of thread) |

d |

D |

s |

Number of teeth |

The weight of every 1000 steel products is ≈kg |

||

|

min |

max |

min |

max |

min |

|||

|

2 |

2.2 |

2.45 |

4.2 |

4.5 |

0.3 |

6 |

0.2 |

|

2.5 |

2.7 |

2.95 |

5.2 |

5.5 |

0.3 |

6 |

0.2 |

|

3 |

3.2 |

3.5 |

5.7 |

6 |

0.4 |

6 |

0.4 |

|

4 |

4.3 |

4.6 |

7.64 |

8 |

0.5 |

8 |

0.9 |

|

5 |

5.3 |

5.6 |

9.64 |

10 |

0.6 |

8 |

0.18 |

|

6 |

6.4 |

6.76 |

10.6 |

11 |

0.6 |

8 |

0.19 |

|

8 |

8.4 |

8.76 |

14.6 |

15 |

0.8 |

8 |

0.54 |

|

10 |

10.5 |

10.93 |

17.6 |

18 |

1 |

9 |

0.92 |

|

12 |

12.5 |

12.93 |

20 |

20.5 |

1 |

10 |

1.09 |

|

14 |

14.5 |

14.93 |

23.5 |

24 |

1.2 |

10 |

1.94 |

|

16 |

16.5 |

16.93 |

25.5 |

26 |

1.2 |

12 |

2.07 |

|

18 |

19 |

19.52 |

29.5 |

30 |

1.5 |

12 |

3.66 |

|

20 |

21 |

21.52 |

32.4 |

33 |

1.5 |

12 |

4.34 |