Description

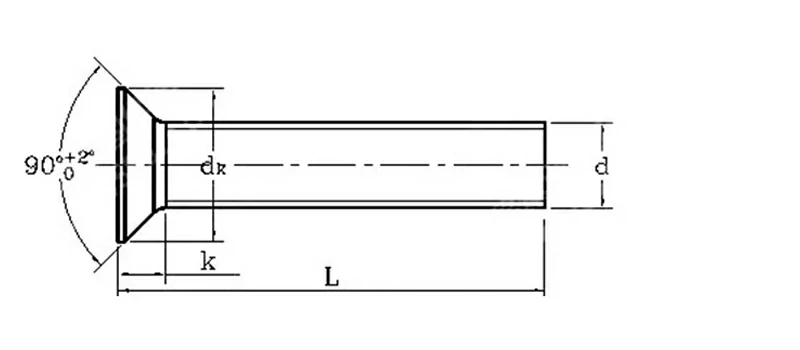

The Cross Recessed Countersunk Head Screw is a high-precision machine screw engineered for applications requiring a flush, clean surface finish and long-term fastening reliability. Manufactured from 316 stainless steel and produced in accordance with the GB819 standard, this screw delivers excellent corrosion resistance, mechanical strength, and dimensional accuracy.

Featuring a countersunk head design and a standard cross recessed (Phillips) drive, this fastener allows for smooth surface integration while ensuring stable torque transfer during installation. Its superior material properties make it particularly suitable for harsh environments such as marine, chemical, and outdoor applications, as well as precision assemblies in electronics, machinery, construction, and furniture manufacturing.

Features & Benefits

- Premium 316 Stainless Steel: Superior corrosion resistance, wear resistance, and oxidation resistance, suitable for humid, marine, and industrial environments.

- Countersunk Head Profile: Allows the screw to sit completely flush with the surface of the component, providing a smooth, clean, and professional aesthetic.

- Standard Cross Groove: Features a standard cross groove drive, making installation easy and ensuring the locking process is not prone to slipping.

- Deep & Uniform Thread: The precisely cut screw thread is deep, ensuring uniform force distribution and a strong, reliable connection.

Specification

|

Nominal diameter -d |

M1.6 |

M2 |

M2.5 |

M3 |

M3.5 |

M4 |

M5 |

M6 |

M8 |

M10 |

|

|

Pitch -p |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

|

|

b |

min |

25 |

25 |

25 |

25 |

38 |

38 |

38 |

38 |

38 |

38 |

|

dk |

max |

3.0 |

3.8 |

4.7 |

5.5 |

7.30 |

8.40 |

9.30 |

11.30 |

15.30 |

18.30 |

|

min |

2.7 |

3.5 |

4.4 |

5.2 |

6.94 |

8.04 |

8.94 |

10.87 |

15.37 |

17.78 |

|

|

k |

max |

1 |

1.2 |

1.5 |

1.65 |

2.35 |

2.7 |

2.7 |

3.3 |

4.65 |

5 |

|

Slot number |

0 |

1 |

2 |

3 |

4 |

||||||

FAQ:

Q1: What is the advantage of a countersunk head screw?

A: A countersunk head allows the screw to sit flush with the surface, improving safety, appearance, and compatibility with moving or exposed components.

Q2: What is the main advantage of 316 stainless steel for these fasteners?

A: 316 stainless steel contains molybdenum, which provides exceptional resistance to pitting and corrosion in chloride-rich environments, such as coastal areas or chemical processing plants. It provides better longevity in harsh conditions compared to 304 stainless steel or coated carbon steel.

Q3: Can these screws be used with a nut?

A: Yes. As these are Machine Screws, they are designed to be used either in a pre-tapped (threaded) hole or with a corresponding nut to secure components together.

Q4: Does the countersunk head require a special hole?

A: Yes. For the screw to sit completely flush, the hole must be "countersunk"—meaning it must have a conical opening that matches the 90-degree angle of the screw head.

Q5: How does the strength of these compare to carbon steel?

A: While 316 stainless steel offers superior corrosion resistance and longevity, high-grade carbon steel (like Grade 8) generally offers higher tensile strength. However, stainless steel is preferred when maintenance must be minimized or when the environment is corrosive.