Description

The Stainless Steel Flange Nut is a high-performance fastening solution designed for applications requiring secure load distribution and resistance to loosening. Featuring a hexagonal nut body with an integrated, non-spinning washer (flange), this fastener eliminates the need for a separate washer while improving joint stability. Manufactured from 304 or 316 stainless steel, it delivers excellent corrosion resistance, strength, and durability in demanding environments.

Stainless steel flange nuts are widely used in automotive, construction, marine, and industrial applications, where vibration resistance, rust prevention, and long service life are critical.

Features & Benefits

- Enhanced Load Distribution: The integrated flange provides a larger bearing surface, which distributes the fastening force more evenly across the material. This reduces the risk of loosening and damage to the fastened part.

- Corrosion Resistance: Made from either 304 or 316 stainless steel, this nut offers excellent resistance to wear, rust, and oxidation, particularly in humid or harsh environments like marine and chemical settings.

- Secure Locking: The flange, often featuring serrations on its underside, provides a locking action that prevents the nut from backing off under vibration. This ensures a secure and firm connection.

- Streamlined Assembly: By combining the nut and washer into a single component, this product simplifies assembly and reduces part inventory, saving time and effort during installation.

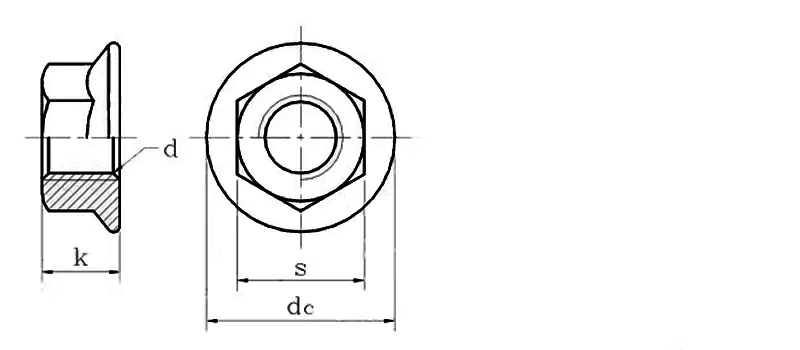

Specification

|

Nominal diameter -d |

PP |

k |

s |

dc |

|||

|

UNC |

max |

min |

max |

min |

max |

min |

|

|

6# |

32 |

0.71 |

0.156 |

0.312 |

0.302 |

0.422 |

0.406 |

|

8# |

32 |

0.203 |

0.187 |

0.344 |

0.334 |

0.469 |

0.452 |

|

10# |

24 |

0.219 |

0.203 |

0.375 |

0.365 |

0.5 |

0.45 |

|

12# |

24 |

0.236 |

0.222 |

0.438 |

0.428 |

0.594 |

0.574 |

|

1/4″ |

20 |

0.236 |

0.222 |

0.438 |

0.428 |

0.594 |

0.574 |

|

5/16″ |

18 |

0.283 |

0.268 |

0.5 |

0.489 |

0.68 |

0.66 |

|

3/8″ |

16 |

0.347 |

0.33 |

0.562 |

0.551 |

0.75 |

0.721 |

|

7/6″ |

14 |

0.395 |

0.375 |

0.688 |

0.675 |

0.937 |

0.91 |

|

1/2″ |

13 |

0.458 |

0.437 |

0.75 |

0.736 |

1.031 |

1 |

|

9/16″ |

12 |

0.506 |

0.483 |

0.875 |

0.861 |

1.188 |

1.155 |

|

5/8″ |

11 |

0.569 |

0.575 |

0.938 |

0.922 |

1.281 |

1.248 |

|

3/4″ |

10 |

0.675 |

0.627 |

1.125 |

1.088 |

0.5 |

1.46 |

FAQ:

Q1: What is the advantage of a stainless steel flange nut compared to a standard hex nut?

A: A flange nut combines a nut and washer into one piece, providing better load distribution, improved vibration resistance, and faster installation compared to a standard stainless steel hex nut.

Q2: When should I choose 316 over 304 for my flange nuts?

A: Choose 304 for general outdoor use, automotive, and construction projects. If your application involves direct exposure to saltwater, coastal air, or aggressive chemicals, 316 stainless steel is the best choice for long-term rust prevention.

Q3: Are serrated flange nuts suitable for all surfaces?

Serrated flange nuts provide excellent locking performance but may mark softer surfaces. For delicate materials, a smooth flange version is recommended.

Q4: Do these nuts have serrations on the bottom?

A: Yes, our hexagon flange nuts are often designed with serrations on the flange face to "bite" into the mating surface, providing an extra layer of security against vibration.

Q5: Are these nuts compatible with standard bolts?

A: Absolutely. As a standard fastener, these nuts are designed to fit seamlessly with any matching thread-size bolt or rod, provided they follow the same standard (Metric or Imperial).