Description

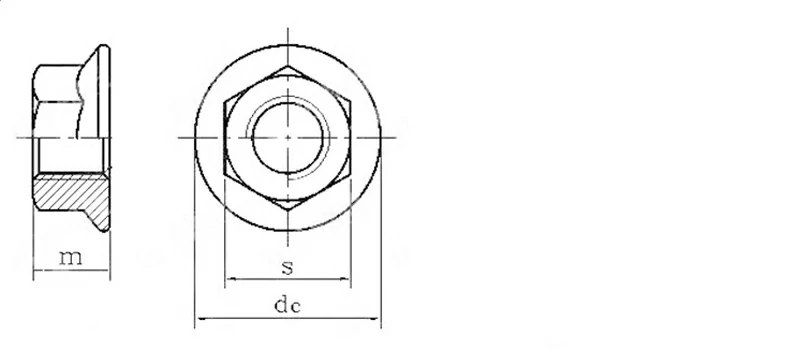

Fine Thread Flange Nuts are high-performance fasteners designed for applications that demand precise adjustment, superior holding strength, and long-term reliability. Manufactured in accordance with the DIN 6923 standard, these nuts combine a fine thread pitch with an integrated flange, delivering enhanced clamping force and resistance to loosening.

Produced from 304 or 316 stainless steel, Fine Thread Flange Nuts offer excellent corrosion resistance, making them suitable for both indoor and outdoor environments. The built-in flange functions as an integrated washer, while the fine threads provide increased contact area with the mating bolt. This combination makes hexagon flange nuts an ideal solution for automotive, machinery, construction, marine, and industrial fastening applications where vibration control and accuracy are critical.

Features & Benefits

- Superior Holding Power: The fine thread pitch provides a larger number of threads per unit of length, which results in a greater contact area. This distributes the load more effectively and makes the nut more resistant to vibration and shock.

- Integrated Flange: The built-in flange acts as an integrated washer, distributing the clamping force over a wider surface area. This helps to prevent damage to the material being fastened and ensures a more stable connection.

- Non-Slip Serrations: The underside of the flange features teeth or serrations that grip the mating surface. This anti-slip design enhances the locking action and prevents the nut from backing off, even under dynamic loads.

- High Corrosion Resistance: Crafted from 304 or 316 stainless steel, our DIN6923 nut is highly resistant to wear, rust, and oxidation, making it ideal for both indoor and outdoor applications, including corrosive and humid environments.

Specification

|

Specification |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M20 |

|

Pitch-P |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

|

Diameter-dc |

9.8 |

11.8 |

14.2 |

17.9 |

21.8 |

26 |

29.9 |

34.5 |

42.8 |

|

Hexagon to side-s |

7 |

8 |

10 |

13 |

15 |

18 |

21 |

24 |

30 |

|

Thickness-m |

4 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

20 |

FAQ:

Q1: Why use a fine thread instead of a standard coarse thread?

A: Fine thread pitch offers a greater contact area between the nut and the bolt, which provides better load distribution and superior resistance to loosening caused by vibration. It also allows for much finer tension adjustments in precision machinery.

Q2: What is the advantage of the serrated flange?

A: The serrations or "teeth" on the underside of the flange grip the mating surface to create a non-slip locking action. This is essential for maintaining a secure connection in applications subjected to frequent movement or dynamic loads.

Q3: Does the DIN 6923 standard ensure compatibility?

A: Absolutely. Adhering to the DIN 6923 standard ensures dimensional accuracy and quality, allowing these fasteners to be used reliably in international industrial assemblies.

Q4: Are DIN 6923 fine thread flange nuts reusable?

A: Yes, they are reusable under normal conditions, provided the threads and serrations are not damaged during installation or removal.

Q5: Are Fine Thread Flange Nuts suitable for high-vibration applications?

Yes. The fine thread pitch combined with serrated flange design provides excellent anti-loosening performance under vibration and dynamic loads.