Description

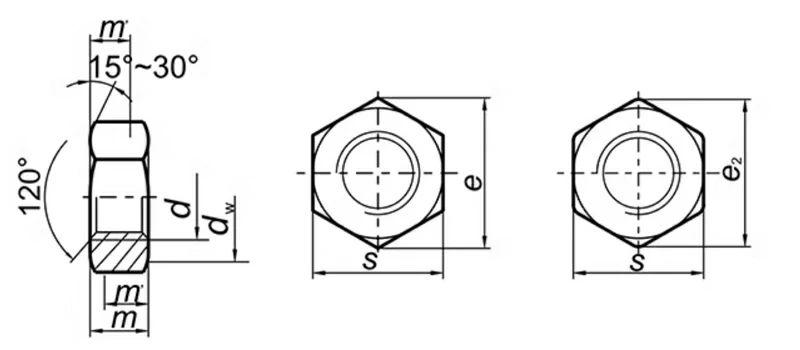

The 2205 Duplex Stainless Steel DIN 934 Nut is a high-performance hexagonal nut engineered for secure fastening in demanding and corrosive environments. Manufactured in strict accordance with the DIN 934 standard, this nut delivers precise dimensions, reliable torque performance, and exceptional mechanical strength.

Made from duplex stainless steel 2205, this DIN 934 nut combines the advantages of austenitic and ferritic stainless steels, resulting in superior yield strength, excellent resistance to stress corrosion cracking, and long-term durability. It is widely used in marine, chemical, industrial, and structural applications where safety, performance, and corrosion resistance are critical.

Features & Benefits

- Superior Strength: The 2205 duplex stainless steel has a yield strength of 400-550 mpa, which is twice that of common austenitic stainless steel. This hexagon nut also has good impact toughness.

- Corrosion Resistance: It offers excellent overall and local resistance to stress corrosion, making it a great choice for highly corrosive environments like chemical processing and marine structures.

- Secure Fastening: The nut is a standard hexagonal part that can lock tightly without slipping. Its deep threads ensure uniform force distribution.

- Non-Slip Threading: The deep, precision-cut threads ensure uniform force distribution, allowing the nut to lock tightly without slipping during installation or operation.

Specification

|

Thread specification -d |

M1 |

M1.2 |

M1.4 |

M1.6 |

M2 |

M2.5 |

M3 |

M3.5 |

M4 |

M5 |

M6 |

M7 |

|

|

P |

0.25 |

0.25 |

0.3 |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

|

|

da |

min |

1 |

1.2 |

1.4 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

|

max |

1.15 |

1.4 |

1.6 |

1.84 |

2.3 |

2.9 |

3.45 |

4 |

4.6 |

5.75 |

6.75 |

7.75 |

|

|

dw |

min |

2 |

2.1 |

2.1 |

2.4 |

3.2 |

4.1 |

4.5 |

5 |

5.8 |

6.8 |

8.8 |

9.5 |

|

e |

min |

2.71 |

3.28 |

3.28 |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

|

m |

max= Nominal size |

0. 8 |

1 |

1.2 |

1.3 |

1.6 |

2 |

2.4 |

2.8 |

3.2 |

4 |

5 |

5.5 |

|

min |

0.55 |

0.75 |

0.95 |

1.05 |

1.35 |

1.75 |

2.15 |

2.55 |

2.9 |

3.7 |

4.78 |

5.2 |

|

|

m′ |

min |

0.44 |

0.6 |

0.76 |

0.84 |

1.08 |

1.4 |

1.72 |

2.04 |

2.32 |

2.96 |

3.76 |

4.16 |

|

s |

max= Nominal size |

2.5 |

3 |

3 |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

|

min |

2.4 |

2.9 |

2.9 |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

|

|

Weight (7.85kg/dm³) ≈kg/ thousand pieces |

0.03 |

0.054 |

0.063 |

0.076 |

0.142 |

0.28 |

0.384 |

0.514 |

0.81 |

1.23 |

2.5 |

3.12 |

|

|

Thread specification -d |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

|

|

M8×1 |

M10×1 |

M12×1.5 |

M14×1.5 |

M16×1.5 |

M18×1.5 |

M20×2 |

||

|

|

M10×1.25 |

M12×1.25 |

|

|

M18×2 |

M20×1.5 |

||

|

P |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

|

|

da |

min |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

max |

8.75 |

10.8 |

13 |

15.1 |

17.3 |

19.5 |

21.6 |

|

|

dw |

min |

11.3 |

15.3 |

17.2 |

20.2 |

22.3IP\ |

25.3 |

28.2 |

|

e |

min |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

32.95 |

|

m |

max= Nominal size |

6.5 |

8 |

10 |

11 |

13 |

15 |

16 |

|

min |

6.14 |

7.64 |

9.64 |

10.3 |

12.3 |

14.3 |

14.9 |

|

|

m′ |

min |

4.91 |

6.11 |

7.71 |

8.24 |

9.84 |

11.44 |

11.92 |

|

s |

max= Nominal size |

13 |

17 |

19 |

22 |

24 |

27 |

30 |

|

min |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

29.16 |

|

|

Weight (7.85kg/dm³) ≈kg/ thousand pieces |

5.2 |

11.6 |

17.3 |

25 |

33.3 |

49.4 |

64.4 |

|

|

Thread specification -d |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

|

|

M22×1.5 |

M24×2 |

M27×2 |

M30×2 |

M33×2 |

M36×3 |

M39×3 |

||

|

M22×2 |

|

|

|

|

|

|

||

|

P |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

|

|

da |

min |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

|

max |

23.7 |

25.9 |

29.1 |

32.4 |

35.6 |

38.9 |

42.1 |

|

|

dw |

min |

29.5 |

33.2 |

38 |

42.7 |

46.6 |

51.1 |

55.9 |

|

e |

min |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

|

m |

max= Nominal size |

18 |

19 |

22 |

24 |

26 |

29 |

31 |

|

min |

16.9 |

17.7 |

20.7 |

22.7 |

24.7 |

27.4 |

29.4 |

|

|

m′ |

min |

13.52 |

14.16 |

16.65 |

18.16 |

19.76 |

21.92 |

23.52 |

|

s |

max= Nominal size |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

|

min |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

|

|

Weight (7.85kg/dm³) ≈kg/ thousand pieces |

79 |

110 |

165 |

223 |

288 |

393 |

8502 |

|

|

Thread specification -d |

M42 |

M45 |

M48 |

M52 |

M56 |

M60 |

M64 |

|

|

M42×3 |

M45×3 |

M48×3 |

M52×3 |

M56×4 |

M60×4 |

M64×4 |

||

|

P |

4.5 |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

da |

min |

42 |

45 |

48 |

52 |

56 |

60 |

64 |

|

max |

45.4 |

48.6 |

51.8 |

56.2 |

60.5 |

64.8 |

69.1 |

|

|

dw |

min |

60.6 |

64.7 |

69.4 |

74.2 |

78.7 |

83.4 |

88.2 |

|

e |

min |

71.3 |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

m |

max= Nominal size |

34 |

36 |

38 |

42 |

45 |

48 |

51 |

|

min |

32.4 |

34.4 |

36.4 |

40.4 |

43.4 |

46.4 |

49.1 |

|

|

m′ |

min |

25.9 |

27.5 |

29.1 |

32.3 |

34.7 |

37.1 |

39.3 |

|

s |

max= Nominal size |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

|

min |

63.1 |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

Weight (7.85kg/dm³) ≈kg/ thousand pieces |

652 |

800 |

977 |

1220 |

1420 |

1690 |

1980 |

|

FAQ:

Q1: What is the main advantage of the DIN 934 Nut in 2205 Duplex steel?

A: The primary advantage is its strength-to-weight ratio and corrosion resistance. It offers twice the yield strength of standard austenitic grades (like 304 or 316), allowing for more secure connections in high-stress environments.

Q2: Can this nut be used in saltwater environments?

A: Yes. The 2205 duplex material is specifically selected for its resistance to localized stress corrosion, making it a "marine grade" standard for offshore and coastal applications.

Q3: Does the "DIN 934" designation mean it fits standard bolts?

A: Absolutely. DIN 934 is a global metric standard for hexagonal nuts. This ensures that the nut will have the correct dimensional accuracy to fit with any corresponding metric fasteners or bolts.

Q4: How does the thread design prevent loosening?

A: The nut is engineered with deep threads that provide a larger surface area for contact. This ensures uniform force distribution and helps the nut "lock tightly," reducing the risk of loosening due to vibration or heavy stress.