Description

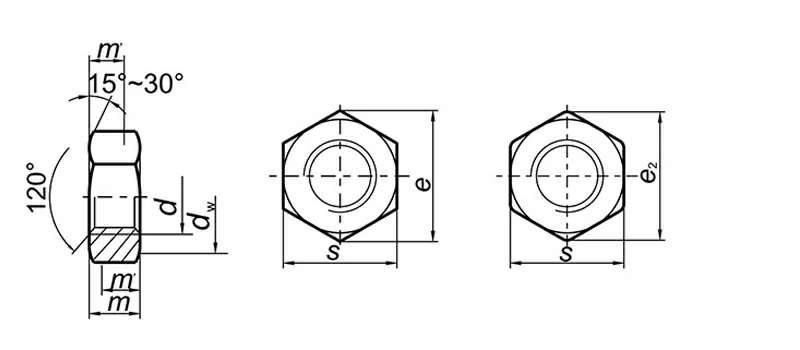

The 304 Stainless Steel DIN934 Hexagon Nut is a full-height, metric hex nut manufactured in accordance with the DIN 934 standard, designed to deliver reliable and secure fastening performance across a wide range of industrial and construction applications. Produced from high-quality 304 stainless steel, this nut offers excellent corrosion resistance, mechanical strength, and long-term durability in demanding environments.

Available in a comprehensive range of metric sizes from M1 to M64, the DIN934 hexagon nut is a widely used standard fastener compatible with metric bolts and threaded rods, making it suitable for machinery, equipment assembly, structural installations, and general-purpose fastening.

Features & Benefits

- High Durability: The nut is made from 304 stainless steel, which provides high wear resistance, strong oxidation resistance, and will not rust in humid environments. It is also highly durable with high hardness and resistance to deformation.

- Standardized Quality: Manufactured according to DIN 934, this hexagon nut meets precise quality and dimensional specifications. Its standard hexagonal shape ensures it is a reliable standard part and is not easy to slip during locking.

- Secure Fastening: The nut features deep, uniform screw threads, ensuring a consistent and strong force distribution when fastened.

- Hexagonal Shape: The hexagonal nut design ensures ease of installation and removal, reducing the chance of slipping during use.

Specification

|

Specification-d |

M1 |

M1.2 |

M1.4 |

M1.6 |

M2 |

M2.5 |

M3 |

M3.5 |

M4 |

M5 |

M16 |

M17 |

|

|

P |

0.25 |

0.25 |

0.3 |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

|

|

da |

min |

1 |

1.2 |

1.4 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

|

max |

1.15 |

1.4 |

1.6 |

1.84 |

2.3 |

2.9 |

3.45 |

4 |

4.6 |

5.75 |

6.75 |

7.75 |

|

|

dw |

min |

2 |

2.1 |

2.1 |

2.4 |

3.2 |

4.1 |

4.5 |

5 |

5.8 |

6.8 |

8.8 |

9.5 |

|

e |

min |

2.71 |

3.28 |

3.28 |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

|

m′ |

max= nominal size |

0.8 |

1 |

1.2 |

1.3 |

1.6 |

2 |

2.4 |

2.8 |

3.2 |

4 |

5 |

5.5 |

|

min |

0.55 |

0.75 |

0.95 |

1.05 |

1.35 |

1.75 |

2.15 |

2.55 |

2.9 |

3.7 |

4.7 |

5.2 |

|

|

m |

min |

0.44 |

0.6 |

0.76 |

0.84 |

1.08 |

1.4 |

1.72 |

2.04 |

2.32 |

2.96 |

3.76 |

4.16 |

|

s |

max= nominal size |

2.5 |

3 |

3 |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

|

min |

2.4 |

2. 9 |

2. 9 |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

0.03 |

0.054 |

0.063 |

0.076 |

0.142 |

0.28 |

0.384 |

0.514 |

0.81 |

1.23 |

2.5 |

3.12 |

|

|

Specification-d |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

|

|

M8×1 |

M10×1 |

M12×1.5 |

M14×1.5 |

M16×1.5 |

M18×1.5 |

M20×2 |

||

|

|

M10×1.25 |

M12×1.25 |

|

|

M18×2 |

M20×1.5 |

||

|

P |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

|

|

da |

min |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

max |

8.75 |

10.8 |

13 |

15.1 |

17.3 |

19.5 |

21.6 |

|

|

dw |

min |

11.3 |

15.3 |

17.2 |

20.2 |

22.2 |

25.3 |

28.2 |

|

e |

min |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

32.95 |

|

m′ |

max= nominal size |

6.5 |

8 |

10 |

11 |

13 |

15 |

16 |

|

min |

6.14 |

7.64 |

9.64 |

10.3 |

12.3 |

14.3 |

14.9 |

|

|

m |

min |

4.91 |

6.11 |

7.71 |

8.24 |

9.84 |

11.44 |

11.92 |

|

s |

max= nominal size |

13 |

17 |

19 |

22 |

24 |

27 |

30 |

|

min |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

29.16 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

5.2 |

11.6 |

17.3 |

25 |

33.3 |

49.4 |

64.4 |

|

|

Specification-d |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

|

|

M22×1.5 |

M24×2 |

M27×2 |

M30×2 |

M33×2 |

M36×3 |

M39×3 |

||

|

M22×2 |

|

|

|

|

|

|

||

|

P |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

|

|

da |

min |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

|

max |

23.7 |

25.9 |

29.1 |

32.4 |

35.6 |

38.9 |

42.1 |

|

|

dw |

min |

29.5 |

33.2 |

38 |

42.7 |

46.6 |

51.1 |

55.9 |

|

e |

min |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

|

m′ |

max= nominal size |

18 |

19 |

22 |

24 |

26 |

29 |

31 |

|

min |

16.9 |

17.7 |

20.7 |

22.7 |

24.7 |

27.4 |

29.4 |

|

|

m |

min |

13.52 |

14.16 |

16.56 |

18.16 |

19.76 |

21.92 |

23.52 |

|

s |

max= nominal size |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

|

min |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

79 |

110 |

165 |

223 |

288 |

393 |

502 |

|

|

Specification-d |

M42 |

M45 |

M48 |

M52 |

M56 |

M60 |

M64 |

|

|

M42×3 |

M45×3 |

M48×3 |

M52×3 |

M56×4 |

M60×4 |

M64×4 |

||

|

P |

4.5 |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

da |

min |

42 |

45 |

48 |

52 |

56 |

60 |

64 |

|

max |

45.4 |

48.6 |

51.8 |

56.2 |

60.5 |

64.8 |

69.1 |

|

|

dw |

min |

60.6 |

64.7 |

69.4 |

74.2 |

78.7 |

83.4 |

88.2 |

|

e |

min |

71.3 |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

m′ |

max= nominal size |

34 |

36 |

38 |

42 |

45 |

48 |

51 |

|

min |

32.4 |

34.2 |

36.4 |

40.4 |

43.4 |

46.4 |

49.4 |

|

|

m |

min |

25.9 |

27.5 |

29.1 |

32.3 |

34.7 |

37.1 |

39.3 |

|

s |

max= nominal size |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

|

min |

63.1 |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

652 |

800 |

977 |

1220 |

1420 |

1690 |

1980 |

|

FAQ:

Q1: What is the DIN 934 standard?

DIN 934 is a German industrial standard that defines the dimensions and mechanical properties of metric hexagon nuts, ensuring consistency and compatibility.

Q2: Why choose 304 stainless steel for hex nuts?

304 stainless steel offers excellent corrosion resistance, good mechanical strength, and durability, making it ideal for general-purpose and mildly corrosive environments.

Q3: Can these nuts be used for high-load machinery?

A: Yes. These nuts feature high hardness and deep, uniform threads designed to ensure strong force distribution and resistance to deformation under load.

Q4: What sizes are available for this hexagon nut?

A: These nuts are available in a comprehensive range of metric sizes, starting from M1 and extending up to M64 to suit diverse industrial needs.

Q5: What bolt types are compatible with this nut?

This nut is compatible with standard metric bolts and threaded rods that meet corresponding metric thread specifications.