Description

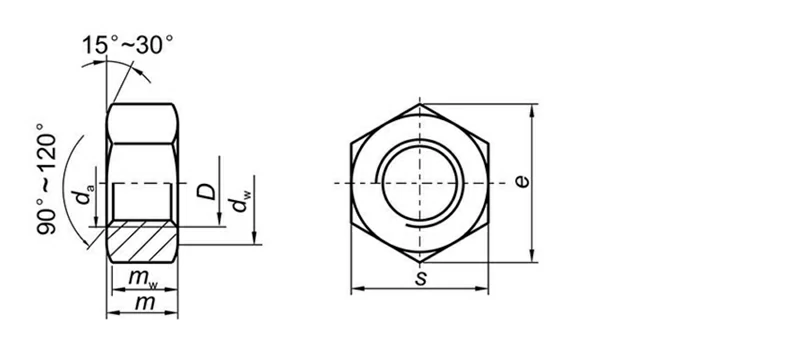

The GB6170 Hexagonal Nut made from 2507 duplex stainless steel is a heavy-duty fastening solution engineered for high-load and corrosive environments. Designed and manufactured in accordance with the GB6170 standard, this thick hexagonal nut provides enhanced strength, dimensional accuracy, and reliable interchangeability in industrial assemblies.

Featuring a thickened construction and deep, precision-cut threads, the 2507 Duplex Steel GB6170 Hexagonal Nut delivers excellent locking performance and uniform load distribution. Its superior mechanical properties and corrosion resistance make it an ideal choice for critical applications in marine engineering, industrial machinery, and chemical processing systems where standard fasteners may not perform adequately.

Features & Benefits

- High Strength and Corrosion Resistance: This thick hexagon nut features high strength, good impact toughness, and excellent resistance to stress corrosion.

- Corrosion Resistance: Outstanding protection against pitting, crevice corrosion, and stress corrosion cracking, suitable for harsh environments like marine and chemical industries.

- Thickened Hexagonal Construction: Provides added durability and ensures tight locking performance without slipping, even under high load or vibration.

- Standardized Design: Conforms to GB6170 specifications for hexagonal nuts, ensuring compatibility and reliable interchangeability in industrial assemblies.

Specification

|

d |

M1.6 |

M2 |

M2.5 |

M3 |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

|

|

e |

min |

3.41 |

4.32 |

5.45 |

6.01 |

7.66 |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

|

m |

max |

1.3 |

1.6 |

2 |

2.4 |

3.2 |

4.7 |

5.2 |

6.8 |

8.4 |

10.8 |

|

min |

1.05 |

1.35 |

1.75 |

2.15 |

2.9 |

4.4 |

4.9 |

6.44 |

8.04 |

10.37 |

|

|

s |

max |

3.2 |

4 |

5 |

5.5 |

7 |

8 |

10 |

13 |

16 |

18 |

|

min |

3.02 |

3.82 |

4.82 |

5.32 |

6.78 |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

|

|

|

The weight of every 1000 steel products is ≈kg |

||||||||||

|

|

0.05 |

0.1 |

0.21 |

0.3 |

0.649 |

1.19 |

2.19 |

4.74 |

8.91 |

13.67 |

|

|

d |

M14 |

M16 |

M20 |

M24 |

M30 |

M36 |

M42 |

M48 |

M56 |

M64 |

|

|

e |

min |

23.36 |

26.75 |

32.95 |

39.55 |

50.85 |

60.79 |

71.3 |

·82.6 |

93.56 |

104.86 |

|

m |

max |

14.1 |

14.8 |

18 |

21.5 |

25.6 |

31 |

34 |

38 |

45 |

51 |

|

min |

13.4 |

14.1 |

16.9 |

20.2 |

24.3 |

29.4 |

32.4 |

36.4 |

43.4 |

49.1 |

|

|

s |

max |

21 |

24 |

30 |

36 |

46 |

55 |

65 |

75 |

85 |

95 |

|

min |

20.67 |

23.67 |

29.16 |

35 |

45 |

53.8 |

63.1 |

73.1 |

82.8 |

92.8 |

|

|

|

The weight of every 1000 steel products is ≈kg |

||||||||||

|

|

21.63 |

32.66 |

58.37 |

100.5 |

205.2 |

351.7 |

534.8 |

816.8 |

1202 |

1659 |

|

FAQ:

Q1: What is the difference between a standard nut and a GB6170 Hexagonal Nut?

A: The GB6170 standard specifies a "thick" construction. This extra thickness provides more thread engagement and higher load-bearing capacity compared to standard-profile nuts.

Q2: Why is 2507 Duplex steel used for these nuts?

A: 2507 duplex stainless steel provides high strength, excellent impact toughness, and outstanding resistance to corrosion and stress corrosion cracking, making it suitable for harsh environments.

Q3: Does this nut require a washer for secure fastening?

A: While the GB6170 nut is designed to lock tightly and distribute load uniformly due to its deep threads, using a compatible 2507 washer can further protect the mating surface in high-vibration industrial machinery.

Q4: Can this fastener be used in saltwater?

A: Yes. The material provides excellent resistance to stress corrosion and pitting, making it a preferred choice for marine engineering and offshore applications.