Description

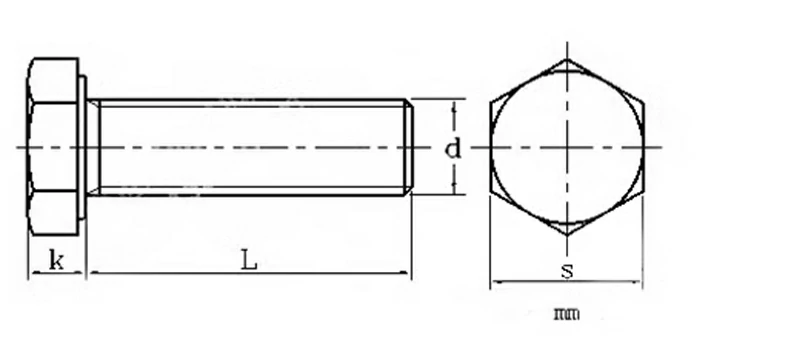

The 321 Stainless Steel DIN 933 Outer Hexagon Bolt is a premium, titanium-stabilized fastener specifically designed to maintain its structural integrity and corrosion resistance in extreme high-temperature environments. Manufactured from 321 stainless steel, a titanium-stabilized alloy, these bolts are specifically designed to prevent intergranular corrosion - particularly after exposure to high temperatures or welding processes. As DIN 933 fully threaded outer hexagon bolts, they feature uniform deep threads, strong torque capability, and excellent structural reliability. Ideal for environments where standard stainless steels such as 304 or 316 may fail, 321 Hex Bolts are commonly used in aerospace, petrochemical, chemical processing, exhaust systems, heat treatment equipment, and structural applications with high thermal loads.

Features & Benefits

- Exceptional High-Temperature Resistance: The titanium stabilization allows the bolt to maintain its strength and corrosion resistance even when exposed to extreme heat, preventing intergranular corrosion.

- Superior Corrosion Resistance: Provides strong resistance to both organic and inorganic acids at various temperatures, ensuring long-term durability in challenging chemical environments.

- High Strength and Hardness: The 321 stainless steel material is strong and practical, offering high hardness and resistance to deformation under stress.

- Standardized & Reliable: Manufactured according to the precise DIN933 standard, guaranteeing a standard external hexagonal head and deep, uniform threads for a secure, non-slip fit.

Specification

|

Specification (d) |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

|

Pitch |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

|

Opposite side (s) |

7 |

8 |

10 |

13 |

17 |

19 |

22 |

24 |

|

Head thickness (k) |

2.8 |

3.4 |

4.1 |

5.3 |

6.8 |

7.5 |

9 |

10 |

|

Specification (d) |

M18 |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

|

Pitch |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

|

Opposite side (s) |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

|

Head thickness (k) |

12 |

12.5 |

14 |

15 |

17 |

19 |

21 |

23 |

FAQs:

Q1: Why choose 321 Hex Bolts over 304 or 316 Stainless Steel?

A: 321 Hex Bolts are specifically chosen for applications operating in high-temperature ranges (425–850°C). Standard 304 and 316 bolts can suffer from sensitization (intergranular corrosion) in this temperature range, but the titanium stabilization in 321 prevents this, maintaining the fastener's strength and corrosion resistance.

Q2: Are 321 Hex Bolts suitable for marine applications?

A: They offer good corrosion resistance, but for saltwater immersion, A4-grade (316) bolts may be preferred. However, 321 performs better at high temperatures.

Q3: Can 321 Hex Bolts be used in chemical processing equipment?

A: Yes. Their corrosion resistance against many acids and chemical agents makes them ideal for industrial and chemical facilities.

Q4: Are these bolts suitable for welding environments?

A: Yes. Unlike many stainless steels, 321 stainless steel is specifically engineered to resist weld decay and maintain integrity after welding.