Description

The Fully Threaded Hex Bolt made from 316L stainless steel is engineered for applications requiring superior corrosion resistance, exceptional strength, and long-term durability. Designed with a standard outer hexagonal head, this hexagon bolt ensures stable fastening, excellent torque transmission, and a secure grip during installation. Its full-thread design provides maximum thread engagement, enabling strong and reliable connections in critical environments. Manufactured in compliance with ANSI B18.2.1, this premium fastener guarantees dimensional accuracy, consistent performance, and compatibility across global industrial applications. With excellent resistance to rust, oxidation, and chemical exposure, the Fully Threaded Hex Bolt is ideal for use in marine, chemical, food processing, construction, equipment assembly, and other demanding fields.

Features & Benefits

- Corrosion Resistance: Crafted from 316L stainless steel, this bolt provides excellent protection against rust and corrosion in harsh environments

- Long-Lasting Durability: Built to last in challenging conditions, this bolt is resistant to wear, corrosion, and oxidation.

- Standard Outer Hexagon: The outer hexagon design makes it easier to grip and tighten, and it provides excellent locking capabilities that prevent slipping during installation.

- Full Threading: The fully threaded design allows for greater thread engagement, offering a stronger and more reliable connection.

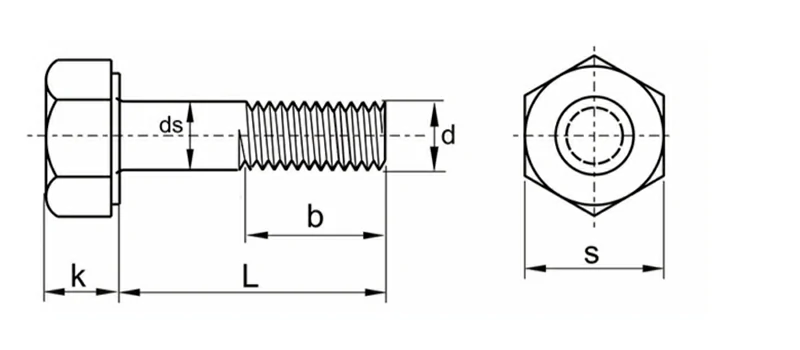

Specification

|

Nominal diameter -d |

ds |

S |

k |

b |

||||

|

max |

min |

max |

min |

max |

min |

L≤6 |

L>6 |

|

|

1/4 |

0.2500 |

0.2450 |

0.438 |

0.428 |

0.163 |

0.150 |

0.750 |

1.000 |

|

5/16 |

0.3125 |

0.3065 |

0.500 |

0.489 |

0.211 |

0.195 |

0.875 |

1.125 |

|

3/8 |

0.3750 |

0.3690 |

0.562 |

0.551 |

0.243 |

0.226 |

1.000 |

1.250 |

|

7/16 |

0.4375 |

0.4305 |

0.625 |

0.612 |

0.291 |

0.272 |

1.125 |

1.375 |

|

1/2 |

0.5000 |

0.4930 |

0.750 |

0.736 |

0.323 |

0.302 |

1.250 |

1.500 |

|

9/16 |

0.5625 |

0.5545 |

0.812 |

0.798 |

0.371 |

0.348 |

1.375 |

1.625 |

|

5/8 |

0.6250 |

0.6170 |

0.938 |

0.922 |

0.403 |

0.378 |

1.500 |

1.750 |

|

3/4 |

0.7500 |

0.7410 |

1.125 |

1.100 |

0.483 |

0.455 |

1.750 |

2.000 |

|

7/8 |

0.8750 |

0.8660 |

1.312 |

1.285 |

0.563 |

0.531 |

2.000 |

2.250 |

|

1 |

1.0000 |

0.9900 |

1.500 |

1.469 |

0.627 |

0.591 |

2.250 |

2.500 |

|

1-1/8 |

1.1250 |

1.1140 |

1.688 |

1.631 |

0.718 |

0.658 |

2.500 |

2.750 |

|

1-1/4 |

1.2500 |

1.2390 |

1.875 |

1.812 |

0.813 |

0.749 |

2.750 |

3.000 |

|

1-3/8 |

1.3750 |

1.3630 |

2.062 |

1.994 |

0.878 |

0.810 |

3.000 |

3.250 |

|

1-1/2 |

1.5000 |

1.4880 |

2.250 |

2.175 |

0.974 |

0.902 |

3.250 |

3.500 |

|

1-3/4 |

1.7500 |

1.7380 |

2.625 |

2.538 |

1. 134 |

1.054 |

3.750 |

4.000 |

|

2 |

2.0000 |

1.9880 |

3.000 |

2.900 |

1.263 |

1.175 |

4.250 |

4.500 |

|

2-1/4 |

2.2500 |

2.2380 |

3.375 |

3.262 |

1.423 |

1.327 |

4.750 |

5.000 |

|

2-1/2 |

2.5000 |

2.4880 |

3.750 |

3.625 |

1.583 |

1.479 |

5.250 |

5.500 |

|

2-3/4 |

2.7500 |

2.7380 |

4.125 |

3.988 |

1.744 |

1.632 |

5.750 |

6.000 |

|

3 |

3.0000 |

2.9880 |

4.500 |

4.350 |

1.935 |

1.815 |

6.250 |

6.500 |

FAQ

Q1: What is the significance of the "L" in 316L Stainless Steel?

A: The "L" stands for Low-Carbon. 316L stainless steel has a lower carbon content than standard 316, which makes it highly resistant to intergranular corrosion (weld decay) that can occur after high-temperature joining processes like welding. This is crucial for applications in chemical environments.

Q2: Why choose a Fully Threaded Hex Bolt?

A: The Fully Threaded Hex Bolt design maximizes thread engagement with the receiving component (nut or tapped hole). This offers a stronger, more secure connection and ensures uniform force distribution, which is ideal for maximum holding power.

Q3: Is this hexagonal head bolt suitable for marine use?

A: Yes. The 316L stainless steel grade is specifically designed for marine environments and applications involving chlorides (saltwater) or chemical exposure, where standard 304 stainless steel would corrode quickly.

Q4: What is the benefit of the Stainless Washing surface treatment?

A: The Stainless Washing surface treatment provides a clean, professional finish, removing any surface contaminants and ensuring the fastener is ready for immediate use in critical or sanitary applications like food processing.