Description

The 304 Stainless Steel U-Bolt is a robust and corrosion-resistant clamping fastener designed for securely mounting, supporting, and fastening round or square components. Formed in a classic “U” shape with precision-threaded ends, this fastener is widely used to anchor pipes, conduits, rods, and cables to structural surfaces.

Manufactured from premium 304 stainless steel, this U-bolt offers excellent resistance to rust and oxidation, making it suitable for both indoor and outdoor environments. Commonly applied in plumbing, construction, marine, and automotive industries, it delivers reliable performance where strength, durability, and long service life are essential.

Features & Benefits

- Corrosion and Oxidation Resistance: Manufactured from 304 stainless steel, these U-bolts are highly resistant to corrosion, rust, and oxidation, even in damp or harsh environments.

- High Strength & Durability: The 304 Stainless Steel U-Bolt is designed with high hardness and is resistant to deformation, ensuring it maintains its structural integrity under heavy loads. The deep, spiral threads provide a uniform force distribution, preventing slippage and ensuring a tight lock.

- Versatile Design: The standard "U" shape allows for a simple and effective installation process, making this bolt a go-to choice for various applications where components need to be securely fastened to a mounting surface.

- Ease of Installation: Threaded ends ensure quick and easy installation with standard nuts, allowing for efficient and secure fastening. The precise threading ensures the bolt locks in place without slipping, providing stability and safety in various applications.

Specification

M6 Series

|

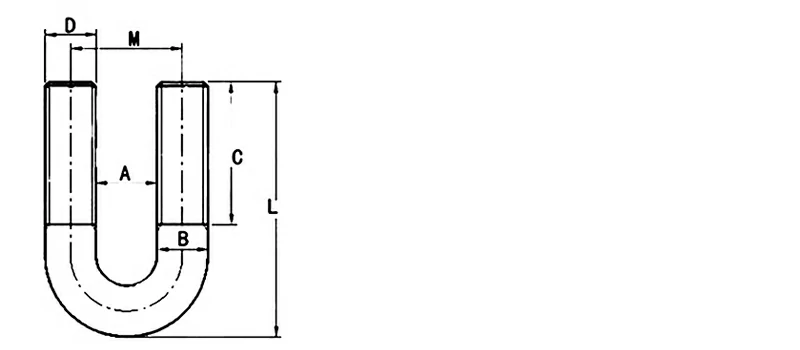

Specification |

A- Pipe diameter |

B- Smooth rod |

C- Tooth length |

D- Diameter |

M- Center distance |

L- Height |

|

M6*8 |

9 |

5.3 |

12 |

6 |

15 |

25 |

|

M6*10 |

11 |

5.3 |

13 |

6 |

17 |

27 |

|

M6*12 |

13 |

5.3 |

14 |

6 |

19 |

29 |

|

M6*14 |

15 |

5.3 |

15 |

6 |

21 |

32 |

|

M6*16 |

17 |

5.3 |

15 |

6 |

23 |

34 |

|

M6*18 |

20 |

5.3 |

18 |

6 |

26 |

36 |

|

M6*22 |

24 |

5.3 |

22 |

6 |

30 |

42 |

|

M6*25 |

27 |

5.3 |

22 |

6 |

33 |

45 |

|

M6*27 |

29 |

5.3 |

25 |

6 |

35 |

47 |

|

M6*33 |

35 |

5.3 |

25 |

6 |

41 |

53 |

|

M6*38 |

40 |

5.3 |

28 |

6 |

46 |

58 |

|

M6*42 |

44 |

5.3 |

28 |

6 |

50 |

62 |

|

M6*45 |

47 |

5.3 |

30 |

6 |

53 |

65 |

|

M6*48 |

50 |

5.3 |

30 |

6 |

56 |

68 |

|

M6*51 |

53 |

5.3 |

30 |

6 |

59 |

71 |

|

M6*57 |

59 |

5.3 |

30 |

6 |

65 |

77 |

|

M6*60 |

62 |

5.3 |

30 |

6 |

68 |

80 |

|

M6*63 |

65 |

5.3 |

30 |

6 |

71 |

83 |

|

M6*76 |

78 |

5.3 |

35 |

6 |

84 |

96 |

|

M6*89 |

91 |

5.3 |

35 |

6 |

97 |

109 |

|

M6*102 |

104 |

5.3 |

35 |

6 |

110 |

122 |

|

M6*108 |

110 |

5.3 |

35 |

6 |

116 |

128 |

|

M6*114 |

116 |

5.3 |

35 |

6 |

122 |

134 |

|

M6*133 |

135 |

5.3 |

35 |

6 |

141 |

153 |

M8 Series

|

Specification |

A- Pipe diameter |

B- Smooth rod |

C- Tooth length |

D- Diameter |

M- Center distance |

L- Height |

|

M8*22 |

24 |

8.9 |

28 |

8 |

32 |

49 |

|

M8*25 |

27 |

8.9 |

28 |

8 |

35 |

52 |

|

M6*27 |

29 |

8.9 |

28 |

8 |

37 |

54 |

|

M6*33 |

35 |

8.9 |

28 |

8 |

43 |

60 |

|

M6*38 |

42 |

8.9 |

30 |

8 |

48 |

65 |

|

M6*42 |

44 |

8.9 |

30 |

8 |

52 |

69 |

|

M8*45 |

47 |

8.9 |

30 |

8 |

55 |

72 |

|

M8*48 |

50 |

8.9 |

35 |

8 |

58 |

65 |

|

M8*51 |

53 |

8.9 |

35 |

8 |

61 |

78 |

|

M8*57 |

59 |

8.9 |

35 |

8 |

67 |

84 |

|

M8*60 |

62 |

8.9 |

35 |

8 |

70 |

87 |

|

M8*63 |

65 |

8.9 |

35 |

8 |

73 |

90 |

|

M8*76 |

78 |

8.9 |

40 |

8 |

86 |

103 |

|

M8*89 |

91 |

8.9 |

40 |

8 |

99 |

116 |

|

M8*102 |

104 |

8.9 |

40 |

8 |

112 |

129 |

|

M8*108 |

110 |

8.9 |

40 |

8 |

118 |

135 |

|

M8*114 |

116 |

8.9 |

45 |

8 |

124 |

141 |

|

M8*133 |

135 |

8.9 |

45 |

8 |

143 |

160 |

|

M8*140 |

142 |

8.9 |

45 |

8 |

150 |

167 |

|

M8*159 |

161 |

8.9 |

50 |

8 |

169 |

189 |

|

M8*168 |

170 |

8.9 |

50 |

8 |

178 |

198 |

|

M8*219 |

221 |

8.9 |

55 |

8 |

229 |

253 |

|

M8*273 |

275 |

8.9 |

55 |

8 |

283 |

313 |

M10 Series

|

Specification |

A- Pipe diameter |

B- Smooth rod |

C- Tooth length |

D- Diameter |

M- Center distance |

L- Height |

|

M10*22 |

24 |

7.1 |

25 |

10 |

34 |

53 |

|

M10*25 |

27 |

7.1 |

25 |

10 |

37 |

56 |

|

M10*27 |

29 |

7.1 |

28 |

10 |

39 |

58 |

|

M10*33 |

35 |

7.1 |

28 |

10 |

45 |

64 |

|

M10*38 |

40 |

7.1 |

30 |

10 |

50 |

69 |

|

M10*42 |

44 |

7.1 |

30 |

10 |

54 |

73 |

|

M10*45 |

47 |

7.1 |

30 |

10 |

57 |

76 |

|

M10*48 |

50 |

7.1 |

30 |

10 |

60 |

82 |

|

M10*51 |

53 |

7.1 |

30 |

10 |

63 |

85 |

|

M10*57 |

59 |

7.1 |

30 |

10 |

69 |

91 |

|

M10*60 |

62 |

7.1 |

30 |

10 |

72 |

94 |

|

M10*63 |

65 |

7.1 |

30 |

10 |

75 |

97 |

|

M10*76 |

78 |

7.1 |

30 |

10 |

88 |

110 |

|

M10*89 |

91 |

7.1 |

30 |

10 |

101 |

123 |

|

M10*102 |

104 |

7.1 |

40 |

10 |

114 |

136 |

|

M10*108 |

110 |

7.1 |

40 |

10 |

120 |

142 |

|

M10*114 |

116 |

7.1 |

40 |

10 |

126 |

148 |

|

M10*133 |

135 |

7.1 |

45 |

10 |

145 |

167 |

|

M10*140 |

142 |

7.1 |

45 |

10 |

152 |

174 |

|

M10*159 |

161 |

7.1 |

50 |

10 |

171 |

193 |

|

M10*168 |

170 |

7.1 |

50 |

10 |

180 |

202 |

|

M10*219 |

221 |

7.1 |

55 |

10 |

231 |

263 |

|

M10*273 |

275 |

7.1 |

65 |

10 |

285 |

322 |

|

M10*219 |

327 |

7.1 |

65 |

10 |

337 |

378 |

|

M10*273 |

379 |

7.1 |

65 |

10 |

389 |

432 |

M12 Series

|

Specification |

A- Pipe diameter |

B- Smooth rod |

C- Tooth length |

D- Diameter |

M- Center distance |

L- Height |

|

M12*42 |

44 |

10.8 |

35 |

12 |

56 |

78 |

|

M12*45 |

47 |

10.8 |

35 |

12 |

59 |

81 |

|

M12*48 |

50 |

10.8 |

35 |

12 |

62 |

84 |

|

M12*51 |

53 |

10.8 |

35 |

12 |

65 |

87 |

|

M12*57 |

59 |

10.8 |

35 |

12 |

71 |

93 |

|

M12*60 |

62 |

10.8 |

35 |

12 |

74 |

96 |

|

M12*63 |

65 |

10.8 |

35 |

12 |

77 |

99 |

|

M12*76 |

78 |

10.8 |

40 |

12 |

90 |

114 |

|

M12*89 |

91 |

10.8 |

40 |

12 |

103 |

127 |

|

M12*102 |

104 |

10.8 |

40 |

12 |

116 |

140 |

|

M12*108 |

110 |

10.8 |

40 |

12 |

122 |

146 |

|

M12*114 |

116 |

10.8 |

40 |

12 |

128 |

152 |

|

M12*133 |

135 |

10.8 |

40 |

12 |

147 |

171 |

|

M12*140 |

142 |

10.8 |

40 |

12 |

154 |

178 |

|

M12*159 |

161 |

10.8 |

55 |

12 |

173 |

200 |

|

M12*168 |

170 |

10.8 |

55 |

12 |

182 |

209 |

|

M12*219 |

221 |

10.8 |

55 |

12 |

233 |

260 |

|

M12*273 |

275 |

10.8 |

55 |

12 |

287 |

314 |

|

M12*325 |

327 |

10.8 |

55 |

12 |

339 |

366 |

|

M12*377 |

379 |

10.8 |

60 |

12 |

391 |

420 |

|

M12*426 |

428 |

10.8 |

60 |

10 |

440 |

472 |

FAQ:

Q1: Can these U-bolts be used for both round and square pipes?

A: Yes. The U-shaped design allows secure fastening of both round and square components when properly sized.

Q2: Are nuts and washers included with the U-bolt?

A: U-bolts are typically supplied with compatible nuts. Washer availability may vary depending on specifications.

Q3: Are custom sizes available?

A: Yes. Custom diameters, thread lengths, and dimensions can be manufactured to meet specific project requirements.

Q4:What industries commonly use the 304 Stainless Steel U-Bolt?

A: These bolts are widely used in plumbing for pipe support, in the marine industry for rigging, and in the automotive sector for securing frames and exhausts.

Q5: How do the threads ensure safety during heavy-duty use?

A: The bolts feature precision-machined, deep spiral threads that distribute force evenly across the fastener, which prevents the bolt from slipping or loosening under load.