Stainless steel fastener galling is a common yet costly issue in construction, industrial, marine, and manufacturing applications. When stainless bolts seize during installation, threads can lock permanently, components may be damaged, and projects face delays and added costs.

Understanding why stainless steel fasteners gall – and how to prevent it—helps engineers, buyers, and installers choose the right galling prevention fasteners and apply best installation practices for reliable performance.

This guide explains what causes galling, how to identify it, and proven ways to prevent stainless steel bolt galling and thread seizing.

What Is Stainless Steel Fastener Galling?

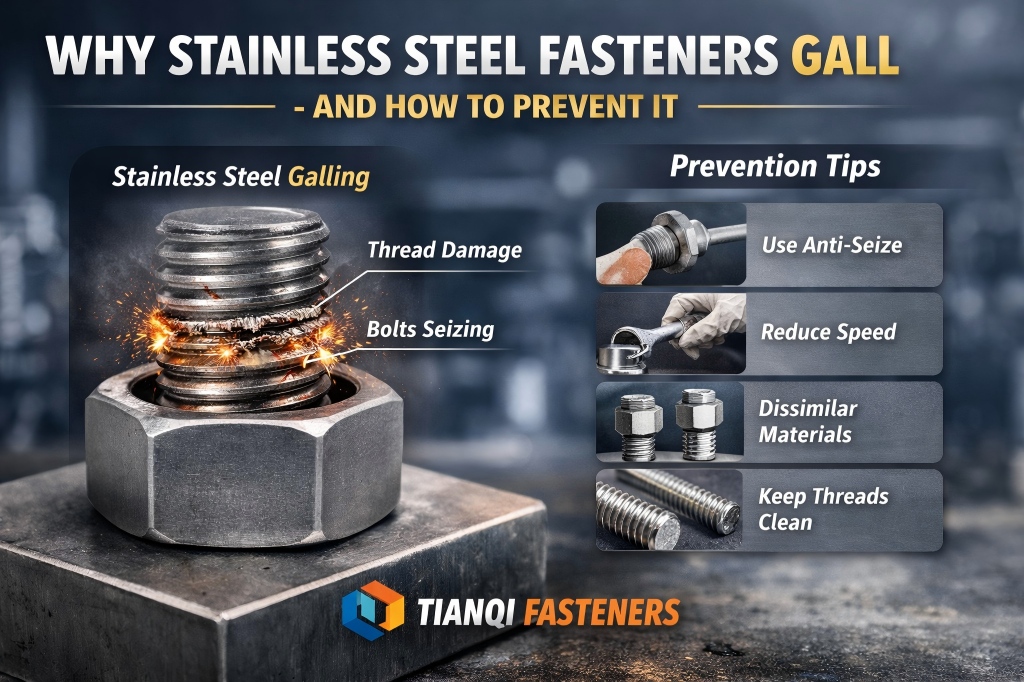

Stainless steel fastener galling often called cold welding – is a form of adhesive wear that occurs when two metal surfaces slide against each other under pressure. During tightening, friction and heat cause microscopic high points on mating threads to weld together.

In cases of stainless steel thread galling, the protective chromium oxide layer is disrupted. As torque increases, welded areas tear apart, transferring material between threads. This leads to stainless steel thread seizing, where the fastener suddenly locks before reaching the required torque.

Once galling starts, the fastener often cannot be removed without cutting or destructive methods.

Why Do Stainless Steel Fasteners Gall?

Although galling can occur in many metals, stainless bolts galling is especially common due to the material’s properties and installation conditions.

1. Material Characteristics of Stainless Steel

Austenitic stainless steels such as 304 and 316 are relatively soft and ductile. While their self-healing oxide layer provides corrosion resistance that lacks a natural lubricating layer, it also increases susceptibility to metal-to-metal adhesion under pressure.

2. High Friction During Installation

Fast tightening speeds – especially with power tools – generate heat quickly. This accelerates adhesion and increases the risk of stainless steel bolt galling.

3. Similar Materials on Both Threads

Using the same stainless steel grade for both the bolt and nut increases the likelihood of galling because similar hardness levels promote material transfer.

4. Fine Threads and Excessive Torque

Fine threads create more surface contact, increasing friction. Over-torquing further raises the risk of stainless steel bolts seizing.

5. Contaminated Threads

Dust, sand, or metal debris act as abrasives, damaging thread surfaces and triggering galling.

Common Signs of Stainless Steel Thread Galling

- Sudden locking during tightening

- Fastener stops turning before reaching torque

- Visible thread damage or metal transfer

- Broken bolts during installation

Once stainless steel thread seizing occurs, replacement is often unavoidable.

How to Prevent Stainless Steel Fastener Galling

Preventing galling is far easier—and less expensive—than fixing it. The following methods are proven to reduce risk:

1. Use Galling Prevention Fasteners

Select galling prevention fasteners that utilize optimized thread geometries, specialized surface treatments, or coatings to minimize adhesion. Coarse threads are often preferred as they reduce friction compared to fine threads.

2. Apply Anti-Seize Lubricants

Applying a nickel-based or molybdenum disulfide anti-seize compound creates a protective barrier between threads. This significantly reduces friction, improves torque control, and dramatically lowers the risk of galling.

3. Reduce Installation Speed

Slow, controlled tightening keeps temperatures low and minimizes the chance of stainless steel thread seizing. Avoid high-speed impact tools when possible.

4. Use Dissimilar Materials

Pairing fasteners with slightly different hardness levels – such as a 304 stainless nut with a 316 stainless bolt – reduces the tendency for threads to weld together.

5. Avoid Over-Torquing

Always follow recommended torque values and adjust for lubrication. Over-tightening is one of the leading causes of stainless steel bolt galling.

6. Keep Threads Clean

Ensure fasteners are free from dirt, grit, and metal shavings before installation. Clean storage conditions also help prevent contamination.

7. Choose High-Quality Threading

Precision-manufactured threads with smooth finishes reduce friction and improve installation reliability.

Applications Where Galling Prevention Is Critical

- Marine and offshore equipment

- Chemical processing systems

- Food and pharmaceutical machinery

- Structural assemblies using stainless steel fasteners

In these environments, corrosion resistance must be paired with reliable, gall-free installation.

Choosing the Right Fasteners for Galling Prevention

When selecting stainless steel fasteners, consider:

- Thread type (coarse threads reduce friction)

- Material grade and surface finish

- Lubrication requirements

- Installation method and torque control

High-quality fasteners designed for galling prevention significantly reduce downtime and assembly failures.

Conclusion

Stainless steel fastener galling is not inevitable. By understanding why stainless bolts gall and applying proven prevention methods – such as lubrication, controlled installation, and high-quality fasteners – you can ensure smooth assembly, consistent torque, and long-term reliability.

Looking for reliable galling prevention fasteners you can trust?

Tianqi Fasteners supplies premium stainless steel bolts, nuts, and screws engineered for smooth installation, consistent quality, and reduced risk of thread seizing.

👉 Contact Tianqi Fasteners today to get expert guidance and high-performance stainless steel fasteners for your next project.