Description

The 2205/2507/321 Stainless Steel Plain Washer is a heavy-duty washer designed to evenly distribute the load of a threaded fastener (bolt or screw) across a larger surface area, helping prevent damage to the material being fastened. Made from high-strength 2205 duplex stainless steel, 2507 super duplex stainless steel, or 321 stainless steel, these washers offer superior corrosion resistance, strength, and high-temperature resistance, making them ideal for demanding applications in harsh environments. Their exceptional durability ensures reliable performance in industries such as construction, automotive, marine, chemical, and food processing.

Features & Benefits

- High Corrosion Resistance: Manufactured from 2205, 2507, or 321 stainless steel, ensuring excellent performance in environments exposed to moisture, chemicals, or extreme conditions.

- Superior Strength & Toughness: Offers high tensile strength and impact toughness, with 2205 duplex stainless steel providing a yield strength of 400-550 MPa, twice that of austenitic stainless steels.

- Uniform Design & Precision: Features standard concentricity, smooth surface, and consistent circular shape for uniform load distribution.

- Large Load-Bearing Surface: The washer's large surface area ensures better load distribution, preventing material deformation, especially for softer materials.

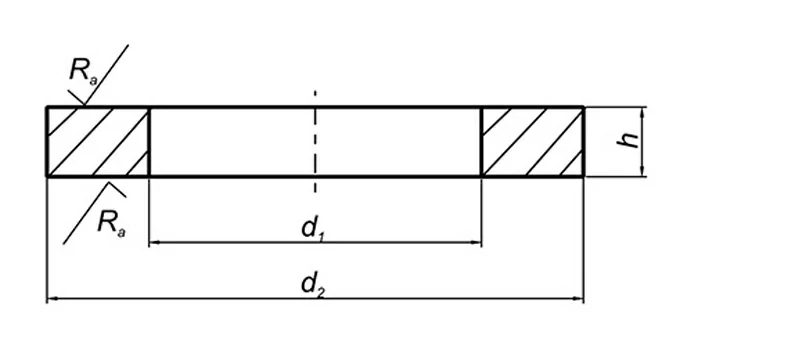

Specification

|

Specification (Thread diameter) |

d1 |

d2 |

h |

The weight of every 1000 steel products is approximately kg |

|||

|

min |

max |

max |

min |

max |

min |

||

|

1.6 |

1.7 |

1.84 |

4 |

3.7 |

0.35 |

0.25 |

0.024 |

|

2 |

2.2 |

2.34 |

5 |

4.7 |

0.35 |

0.25 |

0.037 |

|

2.5 |

2.7 |

2.84 |

6 |

5.7 |

0.55 |

0.45 |

0.088 |

|

3 |

3.2 |

3.38 |

7 |

6.64 |

0.55 |

0.45 |

0.119 |

|

4 |

4.3 |

4.48 |

9 |

8.64 |

0.9 |

0.7 |

0.308 |

|

5 |

5.3 |

5.48 |

10 |

9.64 |

1.1 |

0.9 |

0.443 |

|

6 |

6.4 |

6.62 |

12 |

11.57 |

1.8 |

1.4 |

1.02 |

|

8 |

8.4 |

8.62 |

16 |

15.57 |

1.8 |

1.4 |

1.83 |

|

10 |

10.5 |

10.77 |

20 |

19.48 |

2.2 |

1.8 |

3.57 |

|

12 |

13 |

13.27 |

24 |

23.48 |

2.7 |

2.3 |

6.27 |

|

14 |

15 |

15.27 |

28 |

27.48 |

2.7 |

2.3 |

8.62 |

|

16 |

17 |

17.27 |

30 |

29.48 |

3.3 |

2.7 |

11.30 |

|

20 |

21 |

21.33 |

37 |

36.38 |

3.3 |

2.7 |

17.16 |

|

24 |

25 |

25.33 |

44 |

43.38 |

4.3 |

3.7 |

32.33 |

|

30 |

31 |

31.39 |

56 |

55.26 |

4.3 |

3.7 |

53.64 |

|

36 |

37 |

37.62 |

66 |

64.80 |

5.6 |

4.4 |

92.07 |