Description

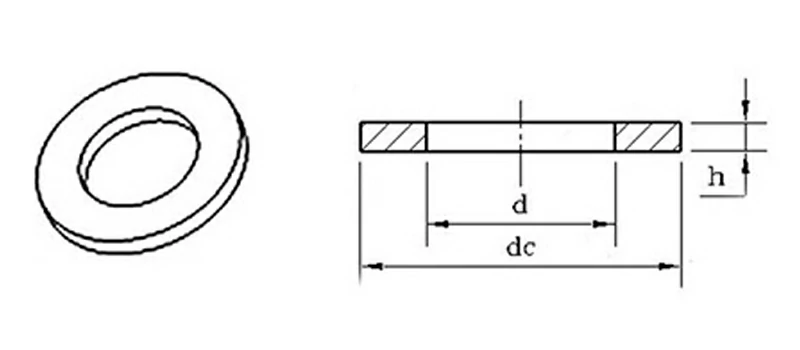

The ANSI B18.22.1 Flat Washer SAE is a plain, flat washer, typically smaller in outer diameter than its USS counterpart, manufactured from either 304 or 316 stainless steel to provide good corrosion resistance, and its dimensions and properties adhere to the American National Standard ANSI B18.22.1. This 304/316 Stainless Steel ANSI B18.22.1 Flat Washer SAE is a high-performance washer designed to improve the strength and durability of fastened joints. They provide reliable load distribution, surface protection, and corrosion resistance, making them essential in demanding industries and environments. The choice between 304 and 316 stainless steel would depend on the specific environmental conditions, with 316 offering superior resistance in more corrosive or high-chloride environments.

Features & Benefits

- High Corrosion Resistance: Made from premium-grade 304 or 316 stainless steel, these washers resist rust, oxidation, and chemical exposure in humid or harsh conditions.

- Durable and Stable: Designed with a smooth, concentric surface for even load distribution, reducing stress and preventing damage to connected parts.

- Precision Standard Compliance: Fully conforms to ANSI B18.22.1 specifications, ensuring dimensional accuracy and reliable performance in American-standard fastening systems.

- Enhanced Strength: Offers excellent mechanical stability and resistance to deformation under heavy loads, making it ideal for demanding applications.

Specification

|

Specification |

6# |

8# |

10# |

12# |

1/4 |

5/6 |

3/8 |

7/16 |

1/2 |

|

|

dc |

max |

9.91 |

11.51 |

13.08 |

14.66 |

16.26 |

17.36 |

21 |

23.8 |

27.74 |

|

min |

9.4 |

11 |

12.57 |

14.15 |

15.75 |

17.3 |

20.45 |

23.24 |

26.8 |

|

|

d |

max |

4.17 |

4.98 |

5.77 |

6.73 |

7.52 |

9.12 |

10.59 |

12.29 |

13.87 |

|

min |

3.84 |

4.65 |

5.44 |

6.22 |

7.01 |

8.61 |

10.19 |

11.79 |

13.36 |

|

|

h |

max |

1.65 |

1.65 |

1.65 |

2.03 |

2.03 |

2.03 |

2.03 |

2.03 |

3.07 |

|

min |

0.91 |

0.91 |

0.91 |

1.3 |

1.3 |

1.3 |

1.3 |

1.3 |

1.88 |

|

|

A thousand pieces weigh in kilograms |

0.66 |

0.85 |

1.09 |

1.74 |

2.13 |

2.24 |

3.37 |

4.26 |

8.8 |

|

|

Specification |

9/16 |

5/8 |

3/4 |

7/8 |

1 |

1-1/8 |

1-1/4 |

1-3/8 |

1-1/2 |

|

|

dc |

max |

30.12 |

34.09 |

38.07 |

45.21 |

51.56 |

57.91 |

64.26 |

70.61 |

76.96 |

|

min |

29.18 |

33.15 |

37.13 |

44.27 |

50.62 |

56.97 |

63.32 |

69.67 |

76.02 |

|

|

d |

max |

15.47 |

17.42 |

21.39 |

24.58 |

27.74 |

32.51 |

35.69 |

38.86 |

42.04 |

|

min |

14.96 |

16.48 |

20.45 |

23.65 |

26.8 |

31.57 |

34.75 |

37.92 |

41.1 |

|

|

h |

max |

3.07 |

3.07 |

4.06 |

4.06 |

4.06 |

4.06 |

4.88 |

4.88 |

4.88 |

|

min |

1.88 |

1.88 |

2.74 |

2.74 |

2.74 |

2.74 |

3.45 |

3.45 |

3.45 |

|

|

A thousand pieces weigh in kilograms |

10.19 |

13.1 |

20.78 |

30.17 |

39.58 |

48.12 |

73.29 |

89.21 |

106.65 |

|