Description

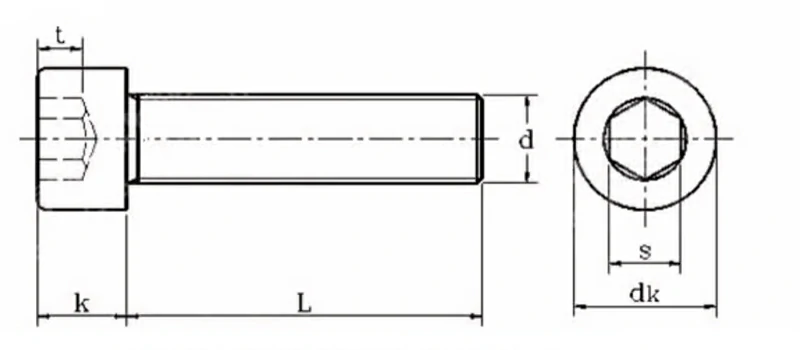

The Hex Head Machine Screw (Socket Head Cap Screw) is a high-performance fastener engineered for the most demanding industrial environments. Combining the precision of the DIN 912 / GB 70.1 standards with elite-grade stainless steel alloys, these stainless steel screws provide a secure, flush finish and the ability to withstand extreme mechanical and environmental stress.

This specialized Hex Socket Screw is designed for projects that exceed the capabilities of standard hardware. By utilizing premium materials like 2205 Duplex, 2507 Super Duplex, and 310S Heat-Resistant stainless steel, these screws offer a unique balance of high tensile strength and specialized chemical or heat resistance.

The cylindrical head and internal hex drive allow for high-torque application, making them a trusted solution for industrial machinery, marine engineering, and chemical processing. Whether you are dealing with high-pressure systems or high-temperature furnaces, these fasteners ensure a reliable, non-slip connection.

Features & Benefits

- High Strength & Durability: The specialized stainless steel alloys provide remarkable strength and toughness, ensuring the screw won't deform or slip under pressure.

- Superior Corrosion Resistance: These screws are highly resistant to rust and corrosion, making them ideal for use in wet, humid, or chemical-rich environments.

- Secure & Accurate Locking: The DIN912 and GB70.1 standards guarantee precise dimensions and a deep thread, ensuring a uniform force distribution and a tight, secure fit that resists loosening.

- Secure Fastening: Internal hex design prevents slippage and ensures efficient torque transfer during installation.

Specification

|

Specification |

Pitch |

Opposite side |

Hexagonal hole depth |

Head diameter |

Head thickness |

|

M1.4 |

0.2 |

0.8 |

0.4 |

2.6 |

1.36 |

|

M1.6 |

0.3 |

1.5 |

0.6 |

2.8 |

1.6 |

|

M2 |

0.4 |

1.5 |

0.8 |

3.6 |

1.8 |

|

M2.5 |

0.45 |

2 |

1 |

4.4 |

2.4 |

|

M3 |

0.5 |

2.2 |

1.3 |

5.3 |

3 |

|

M4 |

0.7 |

3 |

2 |

6.8 |

4 |

|

M5 |

0.8 |

4 |

2.5 |

8.2 |

5 |

|

M6 |

1 |

5 |

3 |

9.8 |

5 |

|

M8 |

1.25 |

6 |

4 |

12.7 |

8 |

|

M10 |

1.5 |

8 |

5 |

15.7 |

10 |

|

M12 |

1.75 |

10 |

6 |

17.7 |

12 |

|

M14 |

2 |

12 |

7 |

20.7 |

14 |

|

M16 |

2 |

13.8 |

8 |

23.8 |

16 |

|

M20 |

2 |

14 |

8 |

24 |

16 |

FAQ:

Q1: What is the difference between 2205, 2507, and 310S stainless steel?

A: 2205 Duplex offers high strength and good corrosion resistance, 2507 Super Duplex provides superior strength and resistance to aggressive corrosion, while 310S stainless steel excels in high-temperature resistance and oxidation stability.

Q2. Do these screws require specialized tools for installation?

A: No, they are compatible with standard hex wrenches or Allen keys. The internal hex drive is designed to prevent stripping, even when applying the high torque required for these heavy-duty alloys.

Q3: Are these screws fully threaded?

A: Depending on the length and application requirements, these can be supplied in full or partial thread variants to ensure maximum clamping force.

Q4: Can custom sizes or materials be supplied?

A: Yes. Custom dimensions, thread pitches, and material grades can be provided upon request to meet specific project requirements.