Description

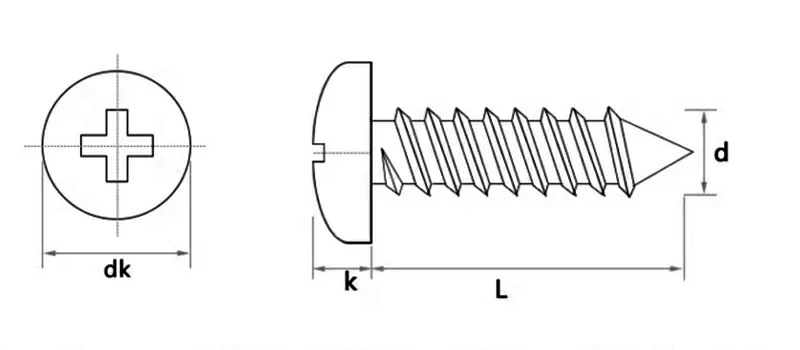

The Stainless Steel Cross Pan Head Self Tapping Screw is a reliable and corrosion-resistant fastening solution designed for fast, efficient assembly across a wide range of materials. Manufactured from high-quality 304 stainless steel, this self-tapping screw is engineered to cut its own mating threads during installation, eliminating or reducing the need for pre-drilled pilot holes in many applications.

Featuring a cross (Phillips) recessed pan head, this screw delivers stable torque transfer, easy installation, and a clean, professional appearance. Its rounded pan head provides a broad bearing surface, ensuring secure clamping without damaging the material surface. Widely used in electronics, automotive components, construction assemblies, and general manufacturing, this fastener offers dependable performance where corrosion resistance and installation efficiency are essential.

Features & Benefits

- High-Quality 304 Stainless Steel: Ensures outstanding corrosion and oxidation resistance, maintaining appearance and integrity even in harsh environments. Offers excellent tensile strength and durability for both structural and precision fastening applications.

- Cross (Phillips) Pan Head Design: Provides a strong driving grip, allowing for easy installation and removal with minimal slipping or cam-out.

- Self-Tapping Thread: Cuts its own thread into materials such as metal, wood, or plastic—reducing assembly time and simplifying installation.

- Smooth Finish and Uniform Threads: Deep, even threading ensures strong holding power, consistent torque, and reduced risk of loosening under vibration.

Specification

|

Thread diameter -d |

M1 |

M1.2 |

M1.4 |

M1.5 |

M1.6 |

M1.7 |

M2 |

M2.3 |

M2.6 |

M3 |

M3.5 |

M4 |

M5 |

M6 |

|

Head diameter -dk |

1.6 |

1.9 |

2.3 |

2.5 |

2.8 |

3 |

3.2 |

3.8 |

4.2 |

5.3 |

6.4 |

7.1 |

9.0 |

11.9 |

|

Head thickness -k |

0.5 |

0.6 |

0.8 |

1.0 |

1.0 |

1.0 |

1.3 |

1.5 |

1.7 |

1.9 |

2.1 |

2.3 |

2.8 |

4.0 |

FAQ:

Q1: What is a self-tapping screw?

A: A self-tapping screw is designed to create its own threads when driven into materials such as metal, plastic, or wood, reducing installation steps and saving time.

Q2: Is a pilot hole always unnecessary for these self-tapping screws?

A: While these screws are designed to cut their own threads, a small pilot hole is often recommended when driving into very hard plastics or thick metals to ensure the screw tracks straight and avoids snapping under high torque.

Q3: Can these screws be reused?

A: Yes, though the self-tapping feature is most effective during the first installation. If reinserted into the same hole, they act more like a standard screw, utilizing the threads they previously cut into the material.

Q4: What is the benefit of the pan head over a countersunk head?

A: The pan head sits on top of the material surface, providing a larger bearing area which is ideal for securing thin sheets or brackets where a flush finish is not required.

Q4: What tools are needed to install this screw?

A: A standard Phillips screwdriver or power driver with the correct bit size is sufficient.