Description

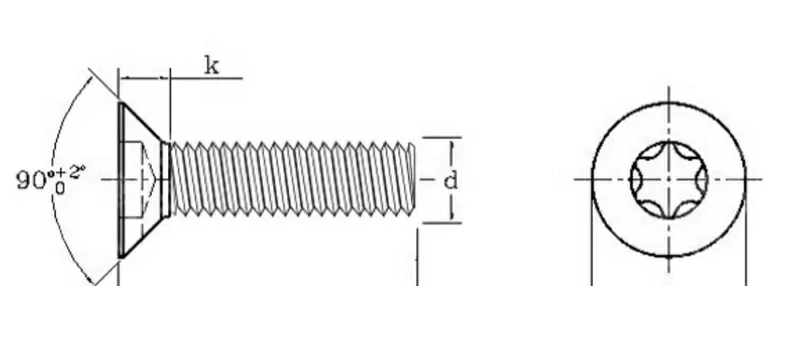

The Countersunk Torx Screw is a precision-engineered fastener designed for applications that require high torque transmission, secure fastening, and a perfectly flush surface finish. Manufactured from premium 304 stainless steel, this screw combines excellent corrosion resistance with dependable mechanical strength, making it suitable for both indoor and outdoor environments.

Featuring a flat countersunk head and an internal Torx (hexalobular) drive, this fastener minimizes cam-out and slippage during installation while enabling higher tightening torque compared to traditional drive types. The countersunk design allows the screw head to sit flush with the material surface, delivering a clean, professional appearance and reducing interference with surrounding components. These characteristics make the Countersunk Torx Screw a reliable solution for electronics, machinery, automotive assemblies, furniture manufacturing, and general industrial fastening applications.

Features & Benefits

- High Corrosion & Oxidation Resistance: Made from high-quality 304 stainless steel, this screw resists rust, corrosion, and oxidation — even in humid or outdoor environments.

- Internal Torx Drive (Plum Groove) : Facilitates high torque capability and makes locking easier, reducing the risk of slipping during fastening.

- High Strength & Dimensional Stability:Excellent hardness and tensile strength ensure dependable fastening under mechanical stress, without deformation.

- Deep, Uniform Thread Design: Precision threading ensures secure engagement, consistent load distribution, and reliable performance across various materials.

Specification

|

Nominal diameter -d |

M3 |

M4 |

M5 |

M6 |

|

|

Pitch -p

|

0.5 |

0.7 |

0.8 |

1 |

|

|

dk |

max |

5.6 |

7.5 |

9.3 |

10.3 |

|

min |

5.5 |

7.4 |

9.2 |

10.2 |

|

|

k |

max |

1.7 |

2.2 |

2.9 |

3.3 |

|

min |

1.6 |

2.1 |

2.8 |

3.2 |

|

|

Suitable for hexagonal wrench |

T10 |

T20 |

T25 |

T30 |

|

FAQ:

Q1: What is the benefit of a Torx (Hexalobular) drive over a Phillips drive?

A: The Torx drive allows for higher torque transfer and significantly reduces the chance of "cam-out" (where the screwdriver slips out of the head). This leads to less damage to the fastener and tools during high-speed assembly.

Q2: Do I need to countersink the hole before installation?

A: Yes. To achieve a perfectly flush finish, the receiving material must be pre-drilled with a conical countersink that matches the angle of the screw head.

Q3: Are these screws magnetic?

A: Mostly no. While carbon steel is strongly magnetic, 304 stainless steel fasteners are generally non-magnetic or only slightly magnetic due to the manufacturing process.

Q4: Does the countersunk head affect structural strength?

A: The countersunk design allows for a flush finish while maintaining reliable clamping force when installed correctly, making it suitable for both structural and aesthetic applications.