Description

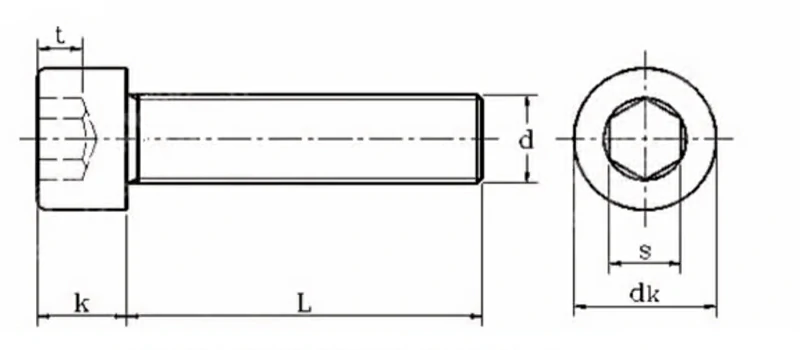

The Hexagon Socket Head Cap Screw DIN 912 is a high-precision fastener featuring a cylindrical head and an internal hexagonal drive, designed for applications requiring high strength, compact installation, and reliable torque transmission. Manufactured from premium 316L stainless steel, this screw delivers exceptional corrosion resistance, mechanical stability, and long-term durability in aggressive and hygienic environments.

Complying strictly with the DIN 912 standard, these hex socket screws offer consistent dimensional accuracy and dependable performance. Their internal hex drive allows for high tightening torque while minimizing the risk of cam-out or slippage, making them an ideal fastening solution for marine, chemical processing, food equipment, aerospace, and industrial machinery applications where reliability is critical.

Features & Benefits

- Corrosion & Wear Resistance: 316L stainless steel construction prevents rust in humid environments and provides strong oxidation resistance.

- High Strength & Stability: The cylindrical head design combined with high material hardness ensures strong clamping force and resistance to deformation under high stress or continuous load.

- Secure Locking: The hex socket drive enables efficient torque transfer using Allen keys, reducing installation slippage and ensuring secure fastening in confined spaces.

- Deep Thread Design: Precisely machined threads provide even load distribution, smooth installation, and enhanced long-term fastening reliability.

Specification

|

Specification |

Pitch |

Opposite side |

Hexagonal hole depth |

Head diameter |

Head thickness |

|

M1.4 |

0.2 |

0.8 |

0.4 |

2.6 |

1.36 |

|

M1.6 |

0.3 |

1.5 |

0.6 |

2.8 |

1.6 |

|

M2 |

0.4 |

1.5 |

0.8 |

3.6 |

1.8 |

|

M2.5 |

0.45 |

2 |

1 |

4.4 |

2.4 |

|

M3 |

0.5 |

2.2 |

1.3 |

5.3 |

3 |

|

M4 |

0.7 |

3 |

2 |

6.8 |

4 |

|

M5 |

0.8 |

4 |

2.5 |

8.2 |

5 |

|

M6 |

1 |

5 |

3 |

9.8 |

5 |

|

M8 |

1.25 |

6 |

4 |

12.7 |

8 |

|

M10 |

1.5 |

8 |

5 |

15.7 |

10 |

|

M12 |

1.75 |

10 |

6 |

17.7 |

12 |

|

M14 |

2 |

12 |

7 |

20.7 |

14 |

|

M16 |

2 |

13.8 |

8 |

23.8 |

16 |

|

M20 |

2 |

14 |

8 |

24 |

16 |

FAQ:

Q1: Why use 316L stainless steel for these screws instead of 304?

A: 316L contains molybdenum and a lower carbon content, which provides significantly better resistance to saltwater, acids, and corrosion than 304 grade. It is the industry standard for marine and chemical applications.

Q2: What tools are required for installation?

A: These screws require a standard hex key (Allen wrench) or a hex-drive power bit. The internal drive allows the head to be recessed or counterbored into the material for a flush finish.

Q3: Is "DIN 912" the same as "ISO 4762"?

A: While they are functionally similar and often interchangeable, DIN 912 is the German standard that has been historically used worldwide for hex socket head cap screws.

Q4: Does the "L" in 316L mean it is weaker?

A: No. The "L" stands for "Low Carbon." While it helps with corrosion resistance (especially near welds), it maintains the high strength and stability required for demanding mechanical loads.

Q5: Are DIN 912 screws suitable for high-load applications?

A: Yes. Their cylindrical head design and deep internal hex drive allow for high clamping force and stable performance under heavy loads.