Description

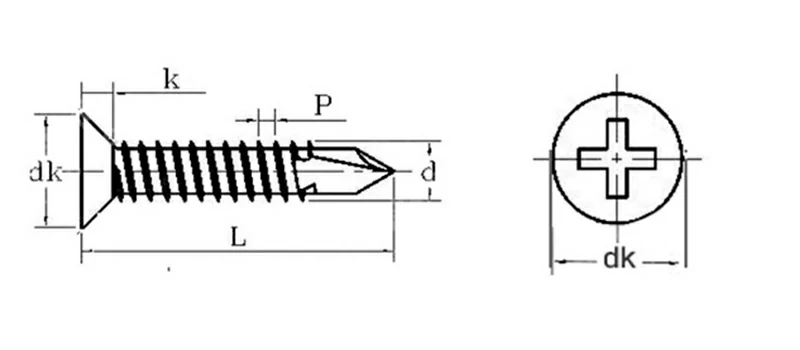

The 410 Stainless Steel Countersunk Self Tapping Self Drilling Screws are precision-engineered fasteners designed to combine the advantages of self-tapping, self-drilling, and countersunk flat head functionality. Made from high-strength 410 stainless steel, these screws offer excellent hardness, wear resistance, and moderate corrosion protection—ideal for indoor and mild outdoor applications. Their cross-groove (Phillips) drive allows easy, stable torque transfer during installation, while the flat countersunk head ensures a smooth, flush finish after fastening. Designed according to DIN 7504P standards, these screws efficiently drill and tap in one step, eliminating the need for pre-drilled pilot holes and reducing installation time. These self tapping screws are widely used in industrial, commercial, and construction environments where secure, efficient fastening and a flush finish are required.

Features & Benefits

- High-Strength 410 Stainless Steel: Offers excellent hardness, tensile strength, and wear resistance, ensuring secure fastening performance even under high torque conditions.

- One-Step Installation: The integrated drill point allows the fastener to drill and tap simultaneously, eliminating the need for pre-drilling and separate tapping, thereby significantly increasing assembly speed and efficiency.

- Secure & Durable: The deep thread design ensures uniform force and a strong, non-slipping lock. It offers good corrosion resistance and oxidation resistance, making it suitable for both indoor and mild outdoor use.

- Slip-Resistant Drive: The standard cross groove drive ensures easy and stable installation with minimal risk of driver slippage.

Specification

|

Specification |

M2.9 |

M3.5 |

M4.2 |

M4.8 |

M5.5 |

M6.3 |

|

Pitch -p |

1.1 |

1.3 |

1.4 |

1.6 |

1.8 |

1.85 |

|

Head diameter -dk |

5.5 |

7.3 |

8.4 |

9.3 |

10.3 |

11.3 |

|

Head thickness -k |

1.7 |

2.35 |

2.6 |

2.8 |

3 |

3.15 |