Description

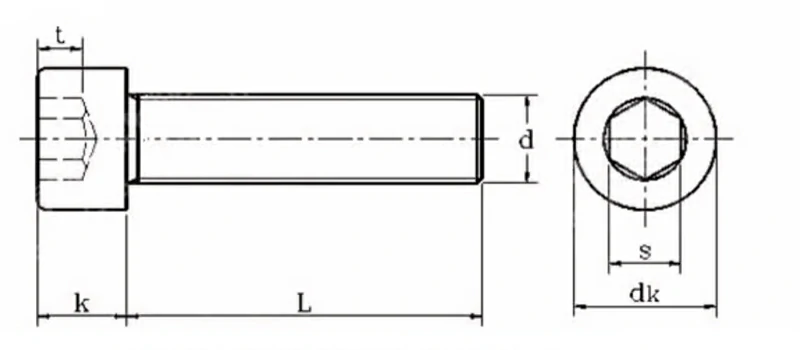

The 316 Stainless Steel Hex Head Screws are premium-grade fasteners designed to provide exceptional performance in environments that demand high strength, precision, and resistance to corrosion. Manufactured from 316 stainless steel, these screws are built to withstand the most challenging conditions, including exposure to moisture, salt, and chemicals. Compliant with DIN 912 standards, they feature a hexagonal socket drive, ensuring secure tightening with minimal risk of slipping.

These screws combine durability and precision threading to offer reliable fastening solutions for industrial, marine, and structural applications. Whether used in construction, chemical plants, or offshore projects, the 316 Stainless Steel Hex Head Screws provide dependable performance, long service life, and enhanced corrosion resistance, making them an essential part of any high-performance fastening system.

Features & Benefits

- Superior Corrosion Resistance: 316 stainless steel ensures long-term performance, even in marine and chemical environments.

- High Durability and Strength: The 316 stainless steel alloy offers exceptional hardness and mechanical strength, ensuring the screw can withstand heavy loads and resist deformation under pressure.

- Standardized and Reliable: Manufactured to the DIN 912 standard, these screws guarantee consistent dimensions and performance, ensuring they integrate seamlessly into a wide range of applications and are compatible with standard tooling.

- Deep, Uniform Threads: The precision-engineered threads provide a smooth, deep engagement with mating parts, ensuring a tight, secure fit and even force distribution.

Specification

|

Specification |

Pitch |

Opposite side |

Hexagonal hole depth |

Head diameter |

Head thickness |

|

M1.4 |

0.2 |

0.8 |

0.4 |

2.6 |

1.36 |

|

M1.6 |

0.3 |

1.5 |

0.6 |

2.8 |

1.6 |

|

M2 |

0.4 |

1.5 |

0.8 |

3.6 |

1.8 |

|

M2.5 |

0.45 |

2 |

1 |

4.4 |

2.4 |

|

M3 |

0.5 |

2.2 |

1.3 |

5.3 |

3 |

|

M4 |

0.7 |

3 |

2 |

6.8 |

4 |

|

M5 |

0.8 |

4 |

2.5 |

8.2 |

5 |

|

M6 |

1 |

5 |

3 |

9.8 |

5 |

|

M8 |

1.25 |

6 |

4 |

12.7 |

8 |

|

M10 |

1.5 |

8 |

5 |

15.7 |

10 |

|

M12 |

1.75 |

10 |

6 |

17.7 |

12 |

|

M14 |

2 |

12 |

7 |

20.7 |

14 |

|

M16 |

2 |

13.8 |

8 |

23.8 |

16 |

|

M20 |

2 |

14 |

8 |

24 |

16 |

FAQ:

Q1: What are the primary applications for 316 Stainless Steel Hex Head Screws?

A: These screws are ideal for marine, chemical, offshore, and industrial applications. Their resistance to corrosion and high tensile strength makes them perfect for environments exposed to saltwater, moisture, and harsh chemicals, such as marine vessels, chemical plants, and outdoor structures.

Q2: How does the hexagonal socket design improve installation?

A: The hexagonal socket provides a strong, secure grip when tightening with a hex key, minimizing the risk of slipping and allowing for efficient and controlled installation. This design ensures that the screws can be tightened to the desired torque without the need for specialized tools.

Q3: Are these screws suitable for permanent outdoor structures?

A: Yes. Due to their high corrosion and oxidation resistance, they are specifically intended for long-term outdoor service life, even in harsh climates.

Q4: What makes 316 stainless steel superior to other materials?

A: 316 stainless steel is known for its exceptional corrosion resistance, particularly in harsh environments like marine and chemical settings. Compared to other types of stainless steel, such as 304 stainless steel, 316 offers enhanced resistance to pitting and crevice corrosion, making it the ideal choice for more aggressive conditions.