Description

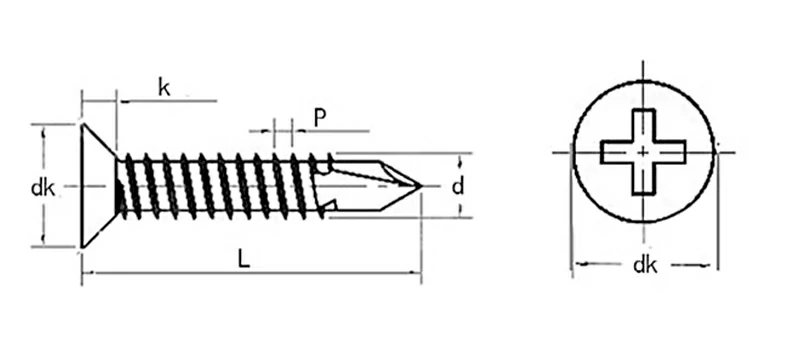

The 316 Stainless Steel Self Drilling Screw is a high-performance fastening solution engineered for demanding environments where corrosion resistance, strength, and installation efficiency are critical. Designed with a cross recessed countersunk head and integrated drilling tail, this screw drills its own pilot hole and forms mating threads in a single operation—eliminating pre-drilling and significantly reducing labor time. Featuring a cross countersunk head, these screws are designed to sit flush with the material surface, providing a smooth, professional aesthetic and improving safety by eliminating protruding edges.

Manufactured from premium 316 stainless steel, this self drilling screw delivers exceptional resistance to rust, oxidation, and chemical corrosion, making it ideal for marine, coastal, industrial, and outdoor applications. The countersunk head ensures a flush, smooth surface finish, providing both functional reliability and a clean, professional appearance across metal, wood, and plastic assemblies.

Features & Benefits

- Premium Stainless Steel Construction: Provides outstanding corrosion resistance in saltwater and chemical environments. The 316 stainless steel body offers excellent mechanical strength and hardness, maintaining thread integrity under heavy load and vibration.

- Cross Countersunk Head Design: Ensures a smooth, flush finish after installation, enhancing both safety and appearance while reducing snagging.

- Self-Drilling Tail: The integrated drill point allows the screw to drill and tap simultaneously, eliminating the need for a pilot hole and reducing labor time.

- Precision Threading: Deep, uniform threads ensure strong holding power, excellent torque transfer, and reliable locking without slippage.

Specification

|

Specification |

M2.9 |

M3.5 |

M4.2 |

M4.8 |

M5.5 |

M6.3 |

|

Pitch -p |

1.1 |

1.3 |

1.4 |

1.6 |

1.8 |

1.85 |

|

Head diameter -dk |

5.5 |

7.3 |

8.4 |

9.3 |

10.3 |

11.3 |

|

Head thickness -k |

1.7 |

2.35 |

2.6 |

2.8 |

3 |

3.15 |

FAQ:

Q1: Why should I use 316 stainless steel instead of 410 for self-drilling screws?

A: While 410 stainless steel is harder and can drill through thicker metal, 316 stainless steel offers far superior corrosion resistance. If your project is near the ocean or involves chemical exposure, 316 is the necessary choice to prevent rust and structural failure.

Q2: Does a countersunk head require a specific pre-drilled hole?

A: Since these are Self Drilling Screws, they create their own hole. however, to achieve the "flush finish," the top of the receiving material must be soft enough for the head to pull in, or a countersink tool can be used to create the conical recess for the head to rest in.

Q3: Can these screws be used for metal-to-metal fastening?

A: Yes. The self-drilling tail is specifically designed to penetrate metal sheets and create threads in a single, accurate operation.

Q4: Is a Phillips (cross) drive the best choice for these?

A: The cross-recess drive is a global standard that allows for easy installation with standard power tools. It provides a reliable connection and good torque transfer for most assembly tasks.

Q5: What is the benefit of a countersunk head?

The countersunk head sits flush with the material surface, offering a smooth finish that improves safety and aesthetics.