Description

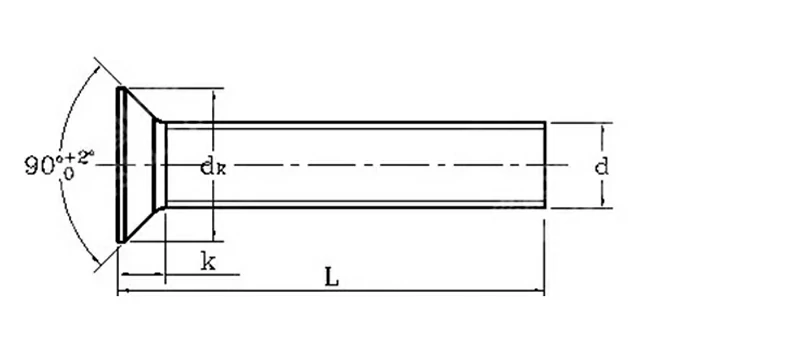

The Cross Countersunk Head Screw is a precision machine screw engineered for applications that require a smooth, flush surface finish combined with reliable fastening strength. Manufactured in accordance with GB819 standards and made from premium 304 stainless steel, this screw delivers excellent corrosion resistance, mechanical stability, and long service life.

Equipped with a standard cross recessed (Phillips) drive, these screws facilitate efficient torque transfer and minimize the risk of slipping during high-speed installation. It is an ideal solution for assemblies where protruding heads are not acceptable. Widely used across electronics, furniture, machinery, and general manufacturing, this screw offers consistent performance in both indoor and moderately corrosive environments.

Features & Benefits

- Flush Finish: The countersunk head shape is specifically designed to fit into a pre-drilled, conical hole, allowing it to sit completely flush with the surface. This is perfect for applications requiring a smooth, non-protruding finish for safety or aesthetics.

- Corrosion & Rust Resistance: Manufactured from high-quality 304 stainless steel, these screws offer superior resistance to rust and corrosion in humid or demanding environments.

- Secure & Stable: The cross-recessed (Phillips) drive ensures easy installation and a tight lock, while the deep, uniform threading provides even force distribution for a secure connection without slippage.

- Versatile Application: This screw is ideal for a wide range of uses, including furniture assembly, electronics, machinery, and other applications where a clean, flush appearance and reliable fastening are critical.

Specification

|

Nominal diameter -d |

M1.6 |

M2 |

M2.5 |

M3 |

M3.5 |

M4 |

M5 |

M6 |

M8 |

M10 |

|

|

Pitch -p |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

|

|

b |

min |

25 |

25 |

25 |

25 |

38 |

38 |

38 |

38 |

38 |

38 |

|

dk |

max |

3.0 |

3.8 |

4.7 |

5.5 |

7.30 |

8.40 |

9.30 |

11.30 |

15.30 |

18.30 |

|

min |

2.7 |

3.5 |

4.4 |

5.2 |

6.94 |

8.04 |

8.94 |

10.87 |

15.37 |

17.78 |

|

|

k |

max |

1 |

1.2 |

1.5 |

1.65 |

2.35 |

2.7 |

2.7 |

3.3 |

4.65 |

5 |

|

Slot number |

0 |

1 |

2 |

3 |

4 |

||||||

FAQ:

Q1: What is the main advantage of a countersunk head?

A: The primary benefit is the "flush finish." Because the head is conical, it sinks into the material so that no part of the screw protrudes above the surface, preventing snags and creating a professional appearance.

Q2: Do I need to pre-drill a hole for these screws?

A: Yes, as these are machine screws, they are intended for use in pre-drilled and pre-tapped holes or in conjunction with a corresponding nut. For a flush finish, the hole must also be countersunk to match the head angle.

Q3: What tools are required for installation?

A: A standard Phillips-head (cross-recess) screwdriver or power bit is all that is required for secure installation and removal.

Q4: Can this screw be used with nuts?

A: Yes, it can be used in pre-tapped holes or paired with compatible nuts, depending on the application.

Q5: Are custom sizes or packaging available?

A: Yes, custom dimensions, bulk packaging, and OEM solutions are available upon request from Tianqi Fasteners.