Description

The Open End Blind Rivet is a high-performance, single-sided mechanical fastener designed for efficient assembly in applications where access is restricted to only one side of the material. Also known as a core-pulling rivet, this model conforms to the Chinese national standard GB/T 12618, ensuring dimensional consistency and quality. This specific rivet utilizes a semi-steel core rivet construction, combining a corrosion-resistant 304 Stainless Steel body (rivet sleeve) with a high-strength steel mandrel (core) for superior shear and tensile strength. The open end allows the mandrel to be pulled through, creating a secure joint without sealing the rivet's tail, making it ideal for non-sealing structural joints. The oval head provides an excellent bearing surface for reliable clamping force. It is commonly used in automotive, marine, electronics, construction, and metal fabrication applications that require durable and secure joints.

Features & Benefits

- Dual Material Construction: The body is made from 304 Stainless Steel, providing high corrosion resistance and a clean, long-lasting aesthetic. The core is a stronger steel alloy, often with a protective surface treatment (White washing), to ensure the mandrel can withstand the pulling force required to form the joint.

- Oval Head Design: The wide, dome-shaped head (oval head) distributes the clamping force over a larger area, protecting soft materials and enhancing the joint's stability against high shear forces.

- Consistent Quality: Conforms to GB12618 standard, guarantees dimensional accuracy, excellent workmanship, and reliable performance across large batches.

- Ease of Installation: The core-pulling mechanism allows for rapid, secure, and permanent fastening using a simple riveting tool, drastically reducing assembly time compared to traditional fasteners.

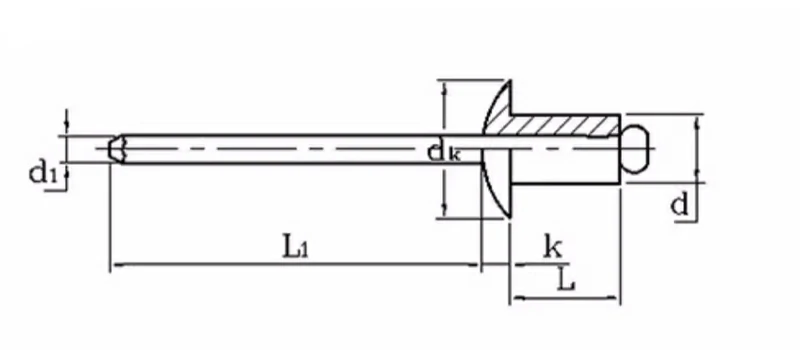

Specification

|

Nominal diameter-d |

dk |

k max |

d1 max |

L1≈ |

|||

|

Nominal-d |

max |

min |

max |

min |

|||

|

2.4 |

2.48 |

2.25 |

5 |

4.2 |

1 |

1.55 |

25 |

|

3 |

3.08 |

2.85 |

6.3 |

5.4 |

1.3 |

2 |

|

|

3.2 |

3.28 |

3.05 |

6.7 |

5.8 |

1.3 |

2 |

|

|

4 |

4.08 |

3.85 |

8.4 |

6.9 |

1.7 |

2.45 |

27 |

|

4.8 |

4.88 |

4.65 |

10.1 |

8.3 |

2 |

2.95 |

|

|

5 |

5.08 |

4.85 |

10.5 |

8.7 |

2.1 |

2.95 |

|

|

6 |

6.08 |

5.85 |

12.6 |

10.8 |

2.5 |

3.4 |

|

|

6.5 |

6.48 |

6.25 |

13.4 |

11.6 |

2.7 |

3.9 |

|

FAQ

Q1: What is the difference between an open-end and closed-end blind rivet?

Open-end blind rivets allow the mandrel movement for expansion and are suitable for general fastening. Closed-end rivets seal the hole to prevent moisture and contamination entry.

Q2: Why choose a semi-steel core instead of full stainless steel?

A semi-steel mandrel provides higher tensile strength and pull-up force at a more cost-effective rate while still ensuring good corrosion resistance.

Q3: Is this rivet suitable for outdoor use?

Yes. The 304 stainless steel body offers excellent resistance to water, moisture, and oxidation, making it ideal for outdoor or marine environments.

Q4: Does the surface treatment affect performance?

No. The white-washing surface treatment is mainly for improved appearance and mild added protection.