Description

The Closed-End Blind Rivet is a high-performance fastener engineered for strong, leak-proof, and corrosion-resistant fastening in applications where access is only available from one side. Designed with a core-pulling (mandrel-pull) mechanism, it ensures secure expansion and a tight, vibration-resistant joint. This unique closed design provides an exceptional advantage by creating a water-tight and airtight barrier, effectively preventing the passage of liquids, gases, or contaminants through the rivet joint. This product complies with GB12615 standards, ensuring precision, reliable performance, and consistent installation quality. Manufactured using 304 stainless steel and aluminum, this closed-end blind rivet offers outstanding durability, moisture resistance, and long-lasting structural integrity - making it ideal for demanding industrial, mechanical, and outdoor environments.

Closed-End Blind Rivets are ideal for applications requiring strong, sealed, and one-side installation fastening, including Automotive & Transportation (vehicle body panels, trailers, cargo compartments), HVAC & Ducting (sealed joints to prevent air and moisture leakage), Electrical & Electronics (sealed enclosures, equipment housing) , Construction & Building Materials, Marine & Outdoor Equipment (corrosion-resistant exposed fastenings) , Metal Fabrication and Machinery Assembly.

Features & Benefits

- Sealed Joint Integrity: Closed-end Design, creates a water-tight and airtight seal, preventing contaminants, moisture, and gases from entering or exiting the assembly.

- One-Sided Installation: Blind Rivet / Core-Pulling Mechanism, allows for fast, secure fastening in structures or cavities where the back side is inaccessible.

- Corrosion & Durability: 304 Stainless Steel / Aluminum Construction, the 304 stainless steel option offers superior high wear resistance and prevents rust in humid environments.

- Precision-Formed Rivet Head: Provides stable clamping force, consistent quality, and a clean professional appearance.

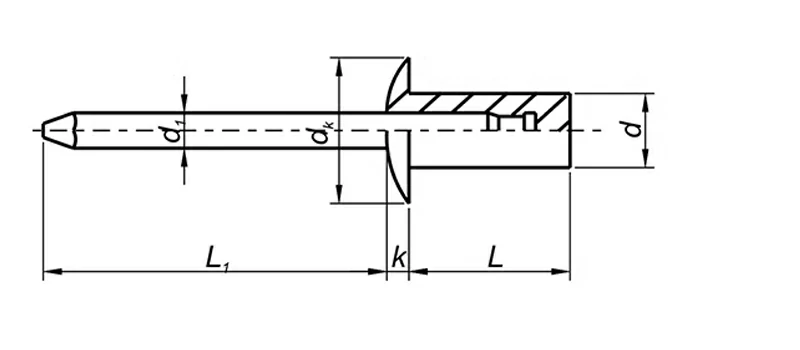

Specification

|

d |

dk |

k max |

R |

r |

d1 |

L1 |

|||

|

Nominal |

max |

min |

max |

min |

≈ |

max |

|||

|

3 |

3.07 |

2.93 |

6.24 |

5.76 |

1.4 |

5 |

0.5 |

1.8 |

26 |

|

3.2 |

3.29 |

3.11 |

6.27 |

5.76 |

1.4 |

5 |

0.5 |

1.8 |

26 |

|

4 |

4.09 |

3.91 |

8.29 |

7.71 |

1.7 |

6.8 |

0.5 |

2.18 |

27 |

|

5 |

5.09 |

4.91 |

8.89 |

9.31 |

2 |

7.6 |

0.7 |

2.8 |

27 |

|

6 |

6.09 |

5.91 |

12.35 |

11.65 |

2.5 |

9.3 |

0.7 |

3.6 |

31 |

FAQ

Q1: What makes a closed-end blind rivet different from a standard blind rivet?

A closed-end design seals the rivet body, preventing leakage of liquids, air, dust, and contaminants - ideal for moisture-sensitive or airtight applications.

Q2: Can these rivets be used outdoors or in corrosive environments?

Yes. Made with 304 stainless steel and aluminum, they provide excellent corrosion and oxidation resistance, suitable for outdoor, humid, or marine environments.

Q3: Do closed-end blind rivets provide vibration resistance?

Yes. The mandrel-pull mechanism forms a strong, shock-resistant joint that helps prevent loosening under vibration.

Q4: What installation tools are required?

A standard blind rivet tool or pneumatic/hydraulic riveter designed for core-pulling rivets is recommended.

Q5: Can sizes be customized?

Yes. Custom lengths, diameters, and head shapes can be manufactured for specific industrial applications.