Description

The 304 Stainless Steel Blind Rivet Nut is a high-strength rivet nut fastener designed to create a reliable, reusable threaded connection in thin or soft materials where conventional tapping is not possible. With a low-profile flat head and blind installation capability, this stainless steel rivet nut provides a secure threaded anchor point when access is available from only one side of the workpiece, and ensures a low-profile, clean finish against the material surface, providing a secure, reusable anchor point for subsequent bolted assemblies. Manufactured from corrosion-resistant 304 stainless steel, it offers excellent durability, oxidation resistance, and long-term performance in demanding environments. This 304 Stainless Steel Blind Rivet Nut is widely used in automotive, aerospace, construction, electronics, machinery, and metal fabrication.

Features & Benefits

- Corrosion Resistance: 304 stainless steel composition. Superior corrosion, wear, and oxidation resistance for indoor & outdoor use.

- Blind Installation: Single-sided setting mechanism. Allows a threaded anchor point to be installed quickly in closed sections or tubes.

- High Strength: Solid construction, high hardness, no deformation. Provides a strong, anti-loose connection, essential for high-vibration applications.

- Strong internal threads: Provides a stable, reusable threaded insert for secure fastening.

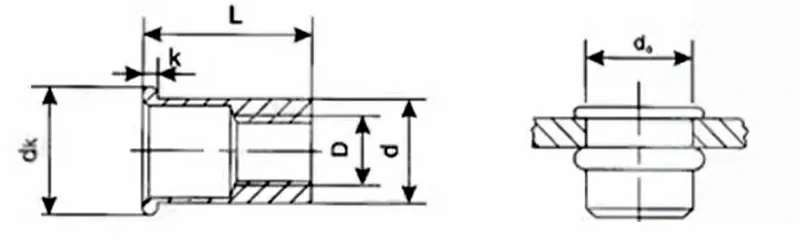

Specification

|

Specification |

M4 |

M5 |

M6 |

M8 |

M10 |

|

Inside Diameter - |

4 |

5 |

6 |

8 |

10 |

|

Outside Diameter - |

5.9 |

6.9 |

8.9 |

10.9 |

12.9 |

|

Inside head diameter - |

6 |

7 |

9 |

11 |

13 |

|

Head outside diameter - |

8.6±1.3 |

9.6±0.3 |

12.3±0.3 |

14.3±0.3 |

16.9±0.3 |

|

Head thickness - |

1.0 |

1.0 |

1.0 |

1.5 |

1.7 |

|

Total length - |

11 |

13 |

15 |

18 |

21 |

FAQ

Q1: Why choose stainless steel over carbon steel rivet nuts?

304 stainless steel provides significantly better corrosion and oxidation resistance, making it ideal for outdoor, marine, and high-moisture environments.

Q2: Can these rivet nuts be installed with standard tools?

Yes. They can be installed using a rivet nut tool/mandrel tool, pneumatic riveter, or manual hand tool depending on size and volume.

Q3: Can the rivet nut be removed?

They are permanent once installed but can be drilled out if replacement is necessary.

Q4: How is a Blind Rivet Nut installed?

The rivet nut is placed into a pre-drilled hole. A specialized tool (hand or pneumatic) pulls the mandrel through the nut's body, causing the body to collapse, or "set," on the blind side of the material, creating a permanent, tight-fitting threaded insert.

Q5: What is the benefit of a Flat Head design?

The Flat Head has a larger bearing surface than a standard countersunk head, providing a stronger mechanical lock against the material. It also presents a minimal, neat profile once installed, which is preferred for many exposed assemblies.