Description

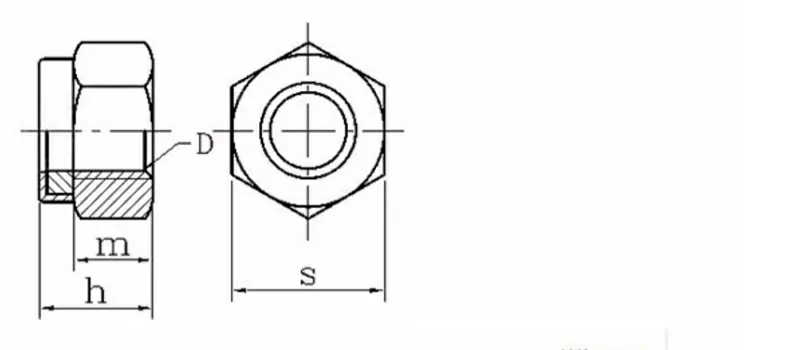

The Hex Nylon Nut manufactured to the DIN 982 standard is a high-performance locking fastener designed for applications requiring superior resistance to vibration, torque, and environmental corrosion. Featuring an integrated nylon insert locking mechanism, this nut creates consistent friction against the mating bolt threads, significantly reducing the risk of loosening during service.

Available in 304, 316, or 316L stainless steel, the DIN 982 Thick Hex Nylon Nut offers enhanced strength, deeper thread engagement, and long-term durability. Its thicker profile compared to standard hex nuts improves load-bearing capacity, making it an ideal choice for industrial, marine, automotive, and mechanical fastening applications where safety and reliability are critical.

Features & Benefits

- Corrosion Resistance: Made from stainless steel (304/316/316L), offering excellent protection against rust and oxidation, even in humid or marine environments.

- Durable Structure: High hardness, wear resistance, and strong deformation resistance ensure long-lasting performance.

- Secure Locking: Nylon insert provides a friction-based locking mechanism, preventing loosening from vibration.

- Thick, Durable Construction: Conforming to the DIN982 standard, this Hex Nylon Nut is thicker than a standard nut, providing increased thread engagement and a more robust connection.

Specification

|

Nominal diameter -D |

Pitch -P |

h |

m |

s |

||

|

max |

min |

min |

max |

min |

||

|

M5 |

0.8 |

6.3 |

6 |

4.4 |

8 |

7.78 |

|

M6 |

1 |

8 |

7.7 |

4.9 |

10 |

9.78 |

|

M7 |

1 |

8.5 |

8.2 |

6.14 |

11 |

10.73 |

|

M8 |

1/1.25 |

9.5 |

9.14 |

6.44 |

13 |

12.73 |

|

M10 |

1/1.25/1.5 |

11.5 |

11.14 |

8.04 |

17 |

16.73 |

|

,M12 |

1.25/1.5/1.7 |

14 |

13.64 |

10.37 |

19 |

18.67 |

|

M14 |

1.5/2 |

16 |

15.3 |

12.1 |

22 |

21.67 |

|

M16 |

1.5/2 |

18 |

17.3 |

14.1 |

24 |

23.67 |

|

M18 |

1.5/2/2.5 |

20 |

19.16 |

15.1 |

27 |

26.16 |

|

M20 |

1.5/2/2.5 |

22 |

20.7 |

16.9 |

30 |

29.16 |

|

M22 |

1.5/2/2.5 |

25 |

23.7 |

18.1 |

32 |

31 |

|

M24 |

2/3 |

28 |

26.7 |

20.2 |

36 |

35 |

FAQ:

Q1: What is the main difference between a DIN 985 and a DIN 982 Hex Nylon Nut?

A: The primary difference is the height. The DIN 982 is a "thick" version, meaning it has a taller body. This provides more thread engagement and a higher load capacity compared to the standard "thin" DIN 985 nylon lock nut.

Q2: What is the advantage of a Hex Nylon Nut over a standard hex nut?

A: Hex Nylon Nut provides built-in locking through a nylon insert, preventing loosening caused by vibration or repeated motion without requiring additional locking components.

Q3: When should I use 316L stainless steel over 316?

A: 316L is a low-carbon version of 316. It is often chosen for applications involving welding or where maximum resistance to intergranular corrosion is required in highly aggressive chemical or saltwater environments.

Q4: Does the nylon insert melt in high temperatures?

A: While the stainless steel body can withstand high heat, the nylon insert typically has a lower temperature threshold. For applications with extreme heat, we recommend consulting our technical team about all-metal locking fasteners.

Q5. Can this Hex Nylon Nut be used multiple times?

A: While they can be reinstalled, the locking effectiveness of the nylon insert reduces with each use as the threads wear down the nylon. For safety-critical industrial applications, we generally recommend using a new nut to ensure the highest locking torque.