Description

Stainless Steel Nylon Insert Lock Nuts are precision-engineered self-locking fasteners designed to deliver superior resistance to vibration, torque, and loosening. Manufactured from high-grade 304 or 316 stainless steel, these nuts incorporate a non-metallic nylon insert that creates a strong frictional grip on the mating bolt threads, ensuring long-term fastening security without damaging the threads.

Conforming to ANSI B18.16.6 standards, these nylon lock nuts provide excellent dimensional accuracy, mechanical reliability, and corrosion resistance. Their robust performance makes them a trusted fastening solution across industries where safety, durability, and maintenance-free operation are critical.

Features & Benefits

- Excellent Corrosion Resistance: Produced from 304 and 316 stainless steel, these nylon insert lock nuts offer outstanding resistance to rust, oxidation, moisture, and chemical exposure, making them suitable for both indoor and outdoor applications.

- Reliable Anti-Loosening Performance: The integrated nylon insert creates a friction-based locking mechanism that resists vibration, shock, and rotational forces, effectively preventing accidental loosening during operation.

- High Strength and Stability: Deep, uniform threads ensure even load distribution, strong engagement with bolts, and consistent torque retention, enhancing overall fastening strength and service life.

- Standards-Compliant Quality: Manufactured in accordance with ANSI B18.16.6, these hex nuts meet strict requirements for dimensional accuracy and performance consistency, ensuring interchangeability and dependable installation.

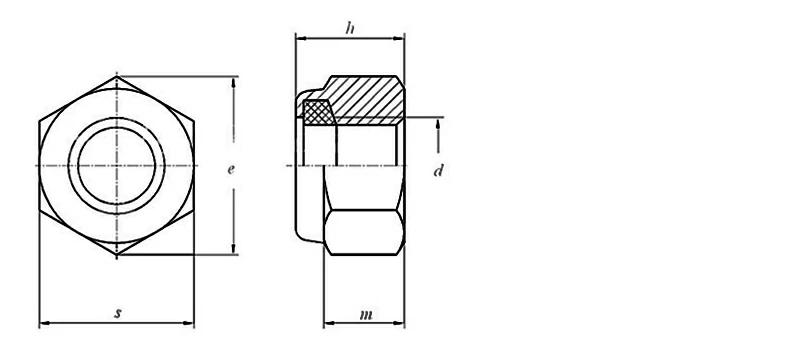

Specification

|

Nominal diameter-d |

2# |

4# |

6# |

8# |

10# |

12# |

|

|

d |

Nominal diameter |

0.056 |

0.112 |

0.138 |

0.164 |

0.19 |

0.216 |

|

PP |

Coarse teeth/UNC |

56 |

40 |

32 |

32 |

24 |

24 |

|

Fine teeth/UNC |

64 |

48 |

40 |

36 |

32 |

28 |

|

|

s |

max |

0.251 |

0.251 |

0.313 |

0.345 |

0.376 |

0.439 |

|

min |

0.243 |

0.243 |

0.305 |

0.336 |

0.367 |

0.43 |

|

|

e |

min |

0.268 |

0.268 |

0.339 |

0.374 |

0.41 |

0.482 |

|

h |

max |

0.153 |

0.153 |

0.188 |

0.239 |

0.249 |

0.328 |

|

min |

0.133 |

0.133 |

0.168 |

0.219 |

0.229 |

0.298 |

|

|

m |

min |

0.081 |

0.081 |

0.103 |

0.14 |

0.14 |

0.225 |

|

Nominal diameter-d |

1/4″ |

5/16″ |

3/8″ |

7/16″ |

1/2″ |

9/16″ |

5/8″ |

|

|

d |

0.25 |

0.3125 |

0.375 |

0.4375 |

0.5 |

0.5625 |

0.625 |

|

|

PP |

UNC |

20 |

18 |

16 |

14 |

13 |

12 |

11 |

|

s |

max |

0.439 |

0.502 |

0.564 |

0.627 |

0.752 |

0.877 |

0.94 |

|

min |

0.43 |

0.489 |

0.551 |

0.616 |

0.736 |

0.861 |

0.922 |

|

|

e |

min |

0.482 |

0.552 |

0.622 |

0.698 |

0.837 |

0.978 |

1.051 |

|

h |

max |

0.328 |

0.359 |

0.468 |

0.468 |

0.609 |

0.656 |

0.765 |

|

min |

0.298 |

0.329 |

0.438 |

0.438 |

0.579 |

0.626 |

0.735 |

|

|

m |

min |

0.225 |

0.25 |

0.335 |

0.324 |

0.464 |

0.469 |

0.593 |

|

Nominal diameter-d |

3/4″ |

7/8″ |

1″ |

1-1/8″ |

1-1/4″ |

1-3/8″ |

1-1/2″ |

|

|

d |

0.75 |

0.875 |

1 |

1.125 |

1.25 |

1.375 |

1.5 |

|

|

PP |

UNC |

10 |

9 |

8 |

7 |

7 |

6 |

6 |

|

s |

max |

1.064 |

1.252 |

1.44 |

1.627 |

1.815 |

2.008 |

2.197 |

|

min |

1.052 |

1.239 |

1.427 |

1.614 |

1.801 |

1.973 |

2.159 |

|

|

e |

min |

1.191 |

1.403 |

1.615 |

1.826 |

2.038 |

2.232 |

2.444 |

|

h |

max |

0.89 |

0.999 |

1.078 |

1.203 |

1.422 |

1.609 |

1.64 |

|

min |

0.86 |

0.969 |

1.016 |

1.141 |

1.36 |

1.547 |

1578 |

|

|

m |

min |

0.742 |

0.79 |

0.825 |

0.93 |

1.125 |

1.282 |

1.313 |

FAQ:

Q1: What is the benefit of the ANSI B18.16.6 standard?

A: This standard ensures that the Stainless Steel Nylon Insert Lock Nuts meet specific American dimensional and performance criteria, providing a predictable fit and consistent locking torque for industrial projects.

Q2: How does the nylon insert prevent loosening?

A: The nylon insert has a smaller diameter than the bolt threads. When the bolt enters the nut, it displaces the nylon, creating a high-friction radial compressive force that "grips" the bolt and prevents it from turning due to vibration.

Q3: Are these nuts suitable for high-vibration machinery?

A: Yes. The primary design goal of the nylon lock nut is to provide a friction-based lock that remains tight under constant vibration, unlike standard nuts that can back off over time.

Q4: Are stainless steel nylon lock nuts reusable?

A: They can be reused in limited cases; however, repeated installations may reduce the locking effectiveness of the nylon insert. For critical applications, replacement is recommended.