Description

The Hex Nylon Lock Nut is a high-performance fastening solution designed to prevent loosening in applications subject to vibration, movement, or dynamic loads. Manufactured from 304 stainless steel and compliant with the DIN 985 standard, this non-metal insert nut features an integrated nylon ring that creates a reliable friction-based locking mechanism.

Unlike standard stainless steel hex nuts, the nylon insert grips the mating bolt threads, maintaining clamping force even under continuous vibration. Combined with the corrosion resistance of 304 stainless steel and a precision-machined hexagonal shape, this fastener delivers long-term reliability in demanding environments such as industrial machinery, automotive assemblies, and marine installations.

Features & Benefits

- Vibration Resistance: The primary feature of the Hex Nylon Lock Nut is its nylon insert, which grips the bolt threads to prevent the nut from vibrating loose. This makes it a dependable choice for applications with dynamic loads or frequent vibrations.

- Corrosion Resistance: Constructed from 304 stainless steel, this nylon nut provides excellent wear resistance and will not rust in humid environments. Its high hardness and strength ensure it is practical and resistant to deformation.

- Secure Fastening: The nut has a standard hexagonal design, making it a standard part that can be tightened easily. The deep threads ensure a uniform force, allowing the nut to lock tightly onto a bolt or a fine thread bolt if applicable.

- Versatile Design: This fastener adheres to the DIN985 standard, ensuring dimensional accuracy and quality for a wide range of industrial applications. While it is a standard hex nut, its unique nylon locking feature sets it apart from a standard hexagon flange nut.

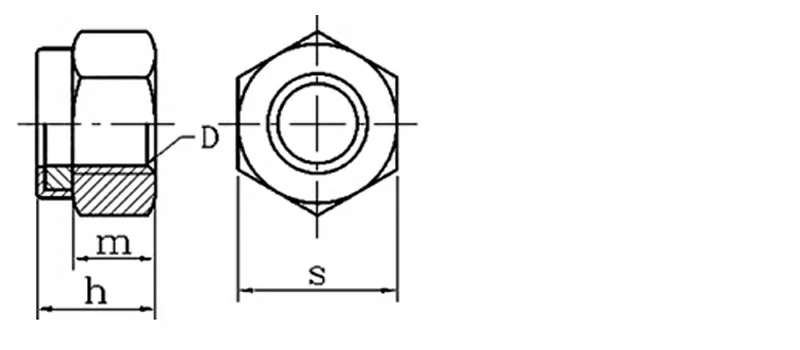

Specification

|

Thread specification-d |

M3 |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

|

|

P |

Pitch (coarse thread) |

0.5 |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

|

Fine teeth |

- |

- |

- |

- |

1 |

1.25 |

1.5 |

1.5 |

1.5 |

2 |

|

|

Fine teeth |

- |

- |

- |

- |

- |

1 |

1.25 |

- |

- |

1.5 |

|

|

e |

min |

6.01 |

7.66 |

8.79 |

11.05 |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

|

h |

max= nominal |

4 |

5 |

5 |

6 |

8 |

10 |

12 |

14 |

16 |

18.5 |

|

min |

3.7 |

4.7 |

4.7 |

5.7 |

7.64 |

9.64 |

11.57 |

13.3 |

15.3 |

17.66 |

|

|

m |

min |

2.4 |

2.9 |

3.2 |

4 |

5.5 |

6.5 |

8 |

9.5 |

10.5 |

13 |

|

s |

max= nominal |

5.5 |

7 |

8 |

10 |

13 |

17 |

19 |

22 |

24 |

27 |

|

min |

5.32 |

6.78 |

7.48 |

9.78 |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

|

|

A thousand jin weighs in kilograms |

0.5 |

1 |

1.4 |

2.4 |

5.1 |

10.6 |

17.2 |

26 |

34 |

45 |

|

|

Thread specification-d |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

M42 |

M45 |

|

|

P |

Pitch (coarse thread) |

2.5 |

2.5 |

3 |

.3 |

3.5 |

3.5 |

4 |

4 |

4.5 |

4.5 |

|

Fine teeth |

2 |

2 |

2 |

2 |

2 |

2 |

3 |

3 |

3 |

3 |

|

|

Fine teeth |

1.5 |

1.5 |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

e |

min |

32.95 |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

72.09 |

76.95 |

|

h |

max= nominal |

20 |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

42 |

45 |

|

min |

18.7 |

20.7 |

22.7 |

25.7 |

28.7 |

31.4 |

34.4 |

37.4 |

40.4 |

43.4 |

|

|

m |

min |

14 |

15 |

15 |

17 |

19 |

22 |

25 |

27 |

29 |

32 |

|

s |

max= nominal |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

65 |

70 |

|

min |

29.16 |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

63.8 |

68.1 |

|

|

A thousand jin weighs in kilograms |

65 |

75 |

100 |

162 |

212 |

317 |

415 |

499 |

628 |

771 |

|

FAQ:

Q1: What is a Hex Nylon Lock Nut?

A: Hex Nylon Lock Nut is a stainless steel hex nut with a built-in nylon insert that provides a self-locking function to prevent loosening under vibration.

Q2: How does the nylon insert work?

A: The nylon ring deforms slightly when the bolt is installed, creating friction against the threads and maintaining clamping force without damaging the bolt.

Q3: Can the Hex Nylon Lock Nut be reused?

A: While these nuts can technically be removed and reapplied, their locking efficiency decreases with each use as the nylon insert conforms to the bolt threads. For critical high-vibration applications, replacing the nut is recommended to ensure maximum safety.

Q4: How does this differ from a standard hexagon flange nut?

A: A hexagon flange nut features a wide, integrated washer-like base to distribute pressure over a larger surface area. The Hex Nylon Lock Nut focuses specifically on preventing loosening due to vibration through its internal nylon insert.

Q5: Does it work with fine-thread bolts?

A: Yes, provided the thread pitch of the nut matches the bolt, the deep-thread design of our lock nuts allows for uniform force and a tight lock on both standard and fine-thread bolts.