Description

The Hexagon Welding Nut manufactured to DIN 929 is a high-performance fastening solution designed for permanent welded connections. Made from premium 304 or 316 stainless steel, this nut is engineered to be welded directly onto metal sheets, plates, or frames, creating a reliable and corrosion-resistant threaded anchor point. Once welded, it provides a strong, vibration-resistant internal thread that can be used repeatedly with standard bolts or screws.

DIN 929 stainless steel hexagon welding nuts are widely used in applications where conventional nuts are difficult to install or where a permanent fastening point is required. Thanks to their excellent corrosion resistance and robust welded structure, they are commonly applied in automotive manufacturing, machinery, marine equipment, food processing systems, and general metal fabrication.

Features & Benefits

- Permanent and Secure Attachment: Once welded, the DIN929 Hexagon Welding Nut provides a durable, non-removable threaded anchor point that is highly resistant to vibration and loosening. The welding projections ensure a strong, stable connection with uniform force distribution.

- Corrosion Resistance: Available in 304 and 316 stainless steel, these nuts offer exceptional resistance to rust and corrosion. The 304 stainless steel grade is perfect for general applications, while the 316 stainless steel provides superior protection in harsh or saline environments like those in the marine or chemical industries.

- Standardized Design: Manufactured to the precise DIN929 standard, these nuts ensure consistent dimensions and reliable performance, making them interchangeable and easy to integrate into a variety of projects.

- Versatile and Reliable: The hexagonal shape allows for easy handling and alignment during the welding process. The deep, uniform threads prevent slipping and ensure a tight, secure fit with a matching bolt.

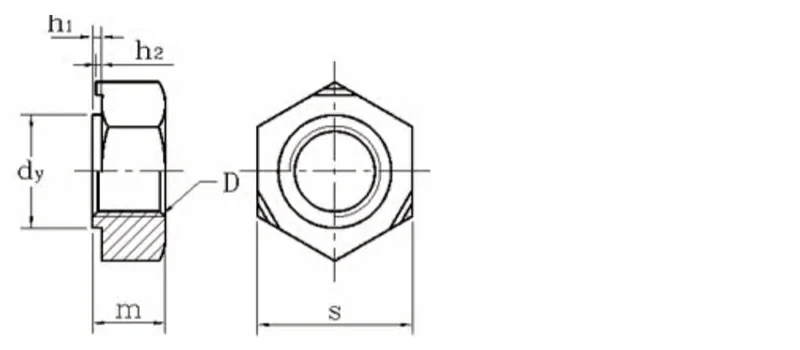

Specification

|

Nominal diameter -D |

Pitch -P |

H1 |

H2 |

m h14 |

s h13 |

dy d11 |

||

|

Nominal |

Allowance |

Nominal |

Allowance |

|||||

|

M3 |

0.5 |

0.55 |

0 -0.1 |

0.25 |

0 -0.1 |

3 |

7.5 |

4.5 |

|

M4 |

0.6 |

0.65 |

0.35 |

3.5 |

9 |

6 |

||

|

M5 |

0.8 |

0.7 |

0.4 |

4 |

10 |

7 |

||

|

M6 |

1 |

0.75 |

0 -0.15 |

0.4 |

5 |

11 |

8 |

|

|

M8 |

1.25 |

0.9 |

0.5 |

0 -0.15 |

6.5 |

14 |

10.5 |

|

|

M10 |

1.5 |

1.15 |

0.65 |

8 |

17 |

12.5 |

||

|

M12 |

1.75 |

1.4 |

0 -0.5 |

0.8 |

0 -0.2 |

10 |

19 |

14.8 |

|

M14 |

2 |

1.8 |

1 |

11 |

22 |

16.8 |

||

|

M16 |

2 |

1.8 |

1 |

13 |

24 |

18.8 |

||

FAQ:

Q1: What is a hexagon welding nut used for?

A: A hexagon welding nut is welded onto a metal surface to create a permanent internal thread, allowing bolts or screws to be installed where access to the reverse side is limited.

Q2: What is the main advantage of a welding nut over a standard hex nut?

A: A Hexagon Welding Nut is designed to be a permanent part of the structure. While a standard hex nut is removable and requires access to both sides of a joint for tightening, a welding nut is fixed in place, allowing for one-sided assembly of bolts in blind or hard-to-reach locations.

Q3: Do these nuts rust during the welding process?

A: Stainless steel is highly resistant to corrosion but not completely rust-proof. High-heat welding can sometimes affect the protective passive layer. To maintain maximum resistance, it is often recommended to passivate the assembly after welding to restore the protective chromium oxide film.

Q4: Can I use carbon steel welding equipment on these stainless nuts?

A:It is important to avoid contamination. Contact with carbon steel tools or particles can transfer iron to the stainless surface, which can lead to localized rusting even on high-quality fasteners.

Q5: Do DIN 929 welding nuts work with standard bolts?

Yes. They are designed with standard metric internal threads and are fully compatible with matching bolts and fasteners.