Description

The Flange Nylon Lock Nut manufactured to DIN 6926 standards is a high-performance fastening solution designed for applications where vibration resistance, load stability, and corrosion protection are critical. Made from premium 304 stainless steel, this nut combines mechanical strength with excellent resistance to rust, oxidation, and environmental exposure.

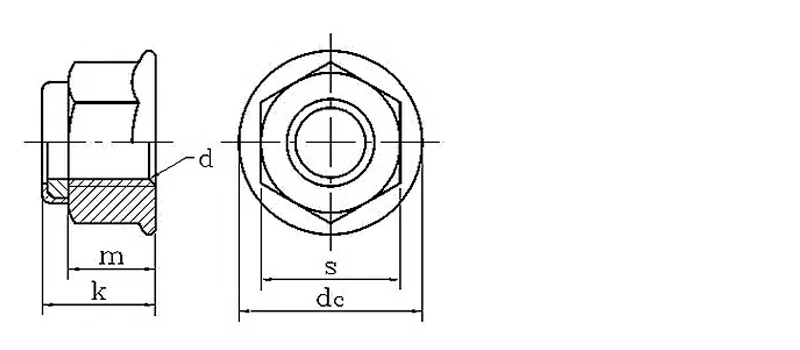

Featuring an integrated hexagonal flange and a built-in nylon insert, this nylon lock nut delivers superior locking performance without the need for additional washers. The flange evenly distributes clamping force across the bearing surface, while the nylon insert creates a reliable friction lock that prevents loosening under vibration, shock, or dynamic loads. As a result, this hex nut is widely used across automotive, machinery, construction, and industrial assembly applications.

Features & Benefits

- Corrosion & Oxidation Resistance: Built from 304 stainless steel, ensuring durability in humid, corrosive, and high-stress environments.

- Secure Locking Mechanism: The nylon insert provides friction-based resistance, preventing loosening under vibration.

- Enhanced Load Distribution: The flange design spreads pressure over a larger surface, reducing the risk of damage to connected parts.

- High Strength & Reliability: Deep, uniform threads ensure strong grip, uniform force distribution, and long service life.

Specification

|

Nominal diameter -d |

Pitch -p |

dc |

k |

m |

s |

||

|

max |

max |

min |

min |

max |

min |

||

|

M4 |

0.7 |

10.5 |

6.5 |

6 |

4.5 |

7 |

6.6 |

|

M5 |

0.8 |

11.8 |

7.1 |

6.74 |

4.7 |

8 |

7.78 |

|

M6 |

1 |

14.2 |

9.1 |

8.74 |

5.7 |

10 |

9.78 |

|

M8 |

1.25 |

17.9 |

11.1 |

10.67 |

7.6 |

13 |

12.73 |

|

M10 |

1.5 |

21.8 |

13.5 |

13.07 |

9.6 |

15 |

14.73 |

|

M12 |

1.75 |

26 |

16.1 |

15.67 |

11.6 |

18 |

17.73 |

|

M14 |

2 |

29.9 |

18.2 |

17.68 |

13.3 |

21 |

20.67 |

|

M16 |

2 |

34.5 |

20.3 |

19.46 |

15.3 |

24 |

23.67 |

|

M20 |

2.5 |

42.8 |

24.8 |

23.96 |

18.9 |

30 |

29.16 |

FAQ:

Q1: What is the difference between a standard nylon lock nut and a flange nylon lock nut?

A: While both use a nylon insert to prevent loosening, the Flange Nylon Lock Nut includes an integrated base that acts as a washer. This makes it better suited for applications where you need to distribute the load over a wider surface area to protect the material being fastened.

Q2: What is the function of the nylon insert in a Flange Nylon Lock Nut?

A: The nylon insert increases friction between the nut and bolt threads, preventing loosening caused by vibration, shock, or repeated motion.

Q3: Can this Flange Nylon Lock Nut be reused?

A: While the stainless steel body remains durable, the nylon insert's locking efficiency decreases slightly with each removal and re-installation. For mission-critical applications, it is generally best practice to use a new nylon lock nut.

Q4: Does the flange replace the need for a washer?

A: Yes. The integrated flange distributes load evenly, eliminating the need for an additional washer in most applications.

Q4: Does the flange have serrations?

A: Standard DIN 6926 nuts typically feature a smooth flange to provide uniform pressure. If your application requires "teeth" to bite into the surface for extra security, please specify if you require a serrated variant.