Description

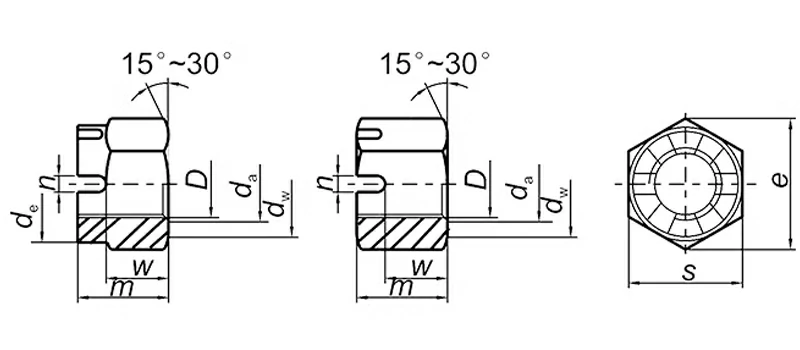

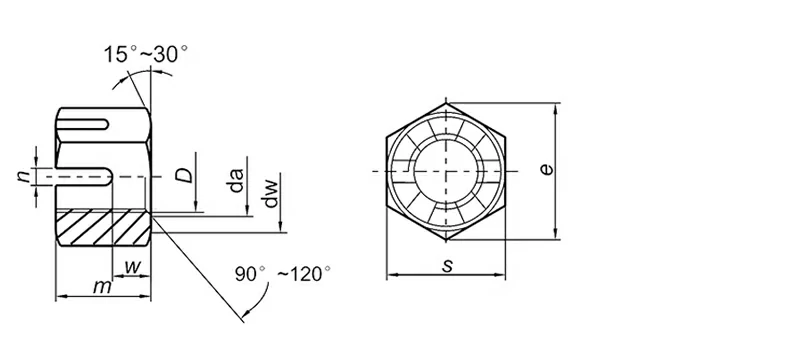

The Hex Slotted Nut is a mechanical locking fastener designed for applications where reliable retention and resistance to loosening are critical. Featuring a hexagonal body with precision-machined slots on the top face, this nut is used in conjunction with a cotter pin or locking wire to prevent rotation after tightening. This positive locking method makes it especially suitable for safety-critical and vibration-prone assemblies.

Manufactured from 304 stainless steel (A2-70) and produced in accordance with GB6178 / GB6181 standards, this Hex Slotted Nut offers excellent corrosion resistance, high mechanical strength, and long service life. It is widely used in automotive systems, industrial machinery, construction equipment, and mechanical assemblies where secure fastening and long-term reliability are required.

Features & Benefits

- Positive Locking Mechanism: The defining feature of a slotted nut is the slots on its top face. A cotter pin or wire is passed through these slots and a hole in the bolt's shank, effectively preventing the nut from rotating or backing off.

- Corrosion-Resistant Material: Made from 304 stainless steel (A2-70), offering superior corrosion resistance, oxidation resistance, and long-term reliability.

- High Strength and Hardness: The 304 stainless steel provides exceptional hardness and strength, resisting deformation under load and preventing the nut from stripping.

- Standardized Design: Manufactured to GB6178/GB6181 standards, this hexagonal nut has a standard shape and deep threads, ensuring a uniform force distribution and preventing slippage during installation.

Specification

GB6178

|

D |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M20 |

M24 |

M30 |

M36 |

|

|

de |

max |

- |

- |

- |

- |

- |

- |

- |

- |

28 |

34 |

42 |

50 |

|

min |

- |

- |

- |

- |

- |

- |

- |

- |

27.16 |

33 |

41 |

49 |

|

|

e |

min |

7.66 |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.35 |

26.75 |

32.95 |

39.55 |

50.85 |

60.79 |

|

m |

max |

5 |

6.7 |

7.7 |

9.8 |

12.4 |

15.8 |

17.8 |

20.8 |

24 |

29.5 |

34.6 |

40 |

|

min |

4.7 |

6.34 |

7.34 |

9.44 |

11.97 |

15.37 |

17.37 |

20.28 |

23.16 |

28.66 |

33.6 |

39 |

|

|

n |

min |

1.2 |

1.4 |

2 |

2.5 |

2.8 |

3.5 |

3.5 |

4.5 |

4.5 |

5.5 |

7 |

7 |

|

max |

1.8 |

2 |

2.6 |

3.1 |

3.4 |

4.25 |

4.25 |

5.7 |

5.7 |

6.7 |

8.5 |

8.5 |

|

|

s |

max |

7 |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

30 |

36 |

46 |

55 |

|

min |

6.78 |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

29.16 |

35 |

45 |

53.8 |

|

|

w |

max |

3.2 |

4.7 |

5.2 |

6.8 |

8.4 |

10.8 |

12.8 |

14.8 |

18 |

21.5 |

25.6 |

31 |

|

min |

2.9 |

4.4 |

4.9 |

6.44 |

8.04 |

10.37 |

12.37 |

14.37 |

17.3 |

20.66 |

24.76 |

30 |

|

|

|

The weight of every 1000 steel products is ≈kg |

||||||||||||

|

|

0.8 |

1.33 |

2.49 |

5.36 |

10.34 |

15.34 |

24.76 |

36.94 |

64.99 |

114.7 |

233.2 |

394.3 |

|

GB6181

|

D |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

M20 |

M24 |

M30 |

M36 |

|

|

e |

min |

8.79 |

11.05 |

14.38 |

17.77 |

20.03 |

23.35 |

26.75 |

32.95 |

39.55 |

50.85 |

60.79 |

|

m |

max |

5.1 |

5.7 |

7.5 |

9.3 |

12 |

14.1 |

16.4 |

20.3 |

23.9 |

28.6 |

34.7 |

|

min |

4. 8 |

5.4 |

7.14 |

8.94 |

11.57 |

13.4 |

15.7 |

19 |

22.6 |

27.3 |

33.1 |

|

|

n |

max |

2 |

2.6 |

3.1 |

3.4 |

4.25 |

4.25 |

5.7 |

5.7 |

6.7 |

8.5 |

8.5 |

|

min |

1.4 |

2 |

2.5 |

2.8 |

3.5 |

3.5 |

4.5 |

4.5 |

5.5 |

7 |

7 |

|

|

s |

max |

8 |

10 |

13 |

16 |

18 |

21 |

24 |

30 |

36 |

46 |

55 |

|

min |

7.78 |

9.78 |

12.73 |

15.73 |

17.73 |

20.67 |

23.67 |

29.16 |

35 |

45 |

53.8 |

|

|

w |

max |

3.1 |

3.2 |

4.5 |

5.3 |

7 |

9.1 |

10.4 |

14.3 |

15.9 |

19.6 |

25.7 |

|

min |

2.8 |

2.9 |

4.2 |

5 |

6.64 |

8.74 |

9.97 |

13.6 |

15.2 |

18.76 |

24.86 |

|

|

|

The weight of every 1000 steel products is ≈kg |

|||||||||||

|

|

0.96 |

1.71 |

3.87 |

7.53 |

11 |

18.38 |

27.67 |

52.74 |

88.88 |

186.1 |

332.9 |

|

FAQ:

Q1: What is the main purpose of a Hex Slotted Nut?

A: Hex Slotted Nut provides a positive mechanical locking method using a cotter pin or wire to prevent the nut from loosening under vibration or load.

Q2: How do I install a Hex Slotted Nut?

A: To install, tighten the Hex Slotted Nut onto a bolt that has a pre-drilled hole in the shank. Align the slots of the nut with the hole in the bolt, then pass a cotter pin through both and bend the ends of the pin to secure the assembly.

Q3: Why use 304 stainless steel for these fasteners?

A: 304 stainless steel is chosen for its excellent balance of strength and corrosion resistance. It is highly resistant to atmospheric corrosion, making it suitable for both indoor and outdoor applications.

Q4: Is a slotted nut the same as a castle nut?

A: While similar, they have a slight structural difference. A castle nut has a cylindrical top section where the slots are located, whereas a Hex Slotted Nut has the slots cut directly into the hexagonal body. Both serve the same primary function of providing a positive mechanical lock.

Q5: Can these nuts rust in marine environments?

A: While 304 stainless steel is highly resistant to rust, it can corrode in salt-rich coastal environments where chlorides break down its protective film. For direct marine use, 316 stainless steel is generally recommended.