Description

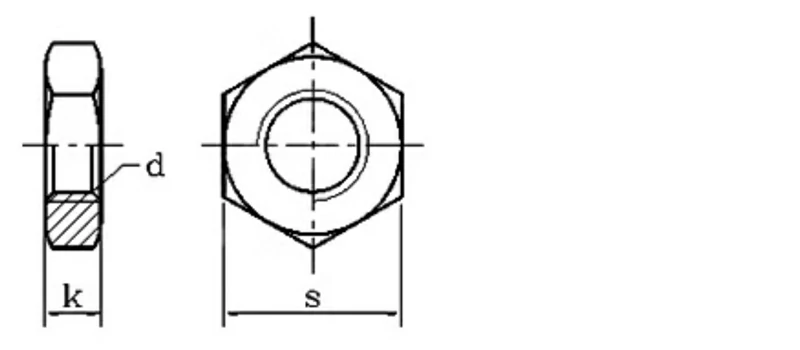

The A2 70 Hex Nut manufactured to the DIN 439 standard is a high-performance, low-profile fastening component engineered for applications where space efficiency, corrosion resistance, and mechanical strength are essential. Made from premium 304 stainless steel (A2), this thin hex nut delivers a minimum tensile strength of 700 MPa, ensuring reliable fastening performance in demanding industrial and architectural environments.

Compared with standard hex nuts, the DIN 439 thin hex nut features a reduced height, making it particularly suitable for assemblies with limited clearance or for use as a secondary locking nut. Its precise dimensions, clean surface finish, and consistent thread quality support smooth installation and long-term stability across a wide range of applications.

Features & Benefits

- High Tensile Strength (A2-70): The A2-70 Hex Nut offers a robust tensile strength of 700 MPa, providing a strong and reliable fastening solution despite its thin profile.

- High Durability: Constructed from 304 stainless steel, offering excellent resistance to corrosion, oxidation, and wear, making it suitable for demanding environments.

- Space-Saving Design: The thin profile of this DIN439 nut is perfect for applications requiring a lightweight, low-profile fastener, or for use as a locking nut in various assemblies.

- Precision Threading: The deep and uniform screw thread ensures a secure lock that is not prone to slipping, providing a strong and dependable connection.

Specification

|

Nominal diameter -d |

Pitch -P |

k |

s |

The mass of every 1000 steel products is ≈kg |

||

|

max |

min |

max |

min |

|||

|

M1.6 |

0.35 |

1 |

0.75 |

3.2 |

3.02 |

0.04 |

|

M2 |

0.4 |

1.2 |

0.95 |

4 |

3.82 |

0.07 |

|

M2.5 |

0.45 |

1.6 |

1.35 |

5 |

4.82 |

0.16 |

|

M3 |

0.5 |

1.8 |

1.55 |

5.5 |

5.32 |

0.22 |

|

M3.5 |

0.6 |

2 |

1.75 |

6 |

5.82 |

0.28 |

|

M4 |

0.7 |

2.2 |

1.95 |

7 |

6.78 |

0.43 |

|

M5 |

0.8 |

2.7 |

2.45 |

8 |

7.78 |

0.66 |

|

M6 |

1 |

3.2 |

2.9 |

10 |

9.78 |

1.29 |

|

M8 |

1.25 |

4 |

3.7 |

13 |

12.73 |

2.72 |

|

M10 |

1.5 |

5 |

4.7 |

17 |

16.73 |

5.21 |

|

M12 |

1.75 |

6 |

5.7 |

19 |

18.67 |

7.51 |

|

M14 |

2 |

7 |

6.42 |

22 |

21.67 |

11.46 |

|

M16 |

2 |

8 |

7.42 |

24 |

23.67 |

17.18 |

|

M18 |

2.5 |

9 |

8.42 |

27 |

26.16 |

23.59 |

|

M20 |

2.5 |

10 |

9.1 |

30 |

29.16 |

31.43 |

|

M22 |

2.5 |

11 |

9.9 |

34 |

33 |

44.85 |

|

M24 |

3 |

12 |

10.9 |

36 |

35 |

54.26 |

|

M27 |

3 |

13.5 |

12.4 |

41 |

40 |

81.19 |

|

M30 |

3.5 |

15 |

13.9 |

46 |

45 |

117.4 |

|

M33 |

3.5 |

16.5 |

15.4 |

50 |

49 |

151.1 |

|

M36 |

4 |

18 |

16.9 |

55 |

53.8 |

202.2 |

|

M39 |

4 |

19.5 |

18.2 |

60 |

58.8 |

260.9 |

|

M42 |

4.5 |

21 |

19.7 |

65 |

63.1 |

325.2 |

|

M45 |

4.5 |

22.5 |

21.2 |

70 |

68.1 |

408.6 |

|

M48 |

5 |

24 |

22.7 |

75 |

73.1 |

509.4 |

|

M52 |

5 |

26 |

24.7 |

80 |

78.1 |

618.9 |

|

M56 |

5.5 |

28 |

26.7 |

85 |

82.8 |

739.2 |

|

M60 |

5.5 |

30 |

28.7 |

90 |

87.8 |

876.9 |

|

M64 |

6 |

32 |

30.5 |

95 |

92.8 |

1027 |

FAQ:

Q1: What is an A2 70 Hex Nut?

A: An A2 70 Hex Nut is a stainless steel hex nut made from A2 (304) material with a minimum tensile strength of 700 MPa, suitable for corrosion-resistant fastening applications.

Q2: When should I use an A2 70 Hex Nut instead of a standard hex nut?

A: Use the A2 70 Hex Nut when you have limited vertical clearance or when you need a "jam nut" to lock a primary fastener in place. Its thin profile allows it to fit into spaces where a standard-height nut would be too bulky.

Q3: Is this nut compatible with a set screw?

A: Yes. These nuts are frequently used to secure a set screw (such as a slotted set screw or a flat end set screw) in place, acting as a locknut to prevent the screw from loosening under vibration.

Q4: Can these nuts be used in the food processing industry?

A: Absolutely. The 304 stainless steel construction provides the necessary corrosion resistance to withstand the moisture and cleaning chemicals common in food-grade environments.