Description

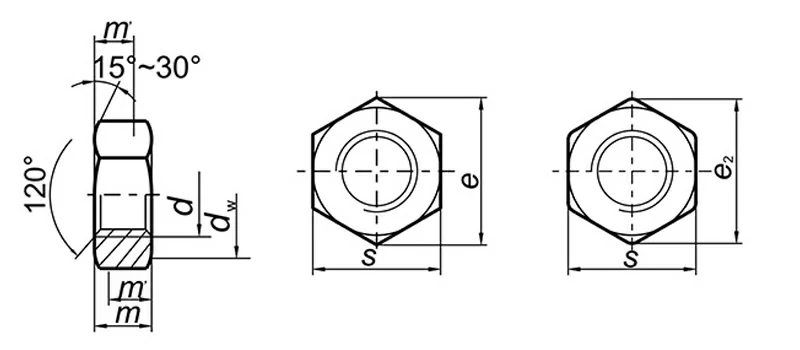

The 2507 Hex Nut is a premium, heavy-duty hexagonal nut manufactured from super duplex stainless steel 2507 and produced in accordance with the DIN 934 standard. Designed for the most aggressive and high-stress environments, this fastener delivers exceptional mechanical strength, superior corrosion resistance, and precise dimensional accuracy.

By combining the tight tolerances of DIN 934 with the outstanding properties of 2507 super duplex stainless steel, this nut provides a secure and durable fastening solution for critical applications. It is commonly used with bolts or threaded rods to ensure stable, long-lasting assemblies in industrial, construction, and machinery systems where performance and safety are paramount.

Features & Benefits

- Extraordinary Strength: The 2507 super duplex stainless steel has a yield strength of 800-1000 mpa, which is twice that of common austenitic stainless steel. It also features good impact toughness.

- Superior Corrosion Resistance: It provides excellent overall and local resistance to stress corrosion. Ideal for applications exposed to seawater, chemicals, or high humidity.

- Secure Fastening: This hexagon nut has a standard hexagonal shape, which ensures it locks without slipping. It also features deep threads for uniform force distribution.

- Standardized Hexagonal Design: The DIN 934 shape ensures compatibility with standard tools and prevents slipping during high-torque applications.

Specification

|

Specification-d |

M1 |

M1.2 |

M1.4 |

M1.6 |

M2 |

M2.5 |

M3 |

M3.5 |

M4 |

M5 |

M6 |

M7 |

|

|

P |

0.25 |

0.25 |

0.3 |

0.35 |

0.4 |

0.45 |

0.5 |

0.6 |

0.7 |

0.8 |

1 |

1 |

|

|

da |

min |

1 |

1.2 |

1.4 |

1.6 |

2 |

2.5 |

3 |

3.5 |

4 |

5 |

6 |

7 |

|

max |

1.15 |

1.4 |

1.6 |

1.84 |

2.3 |

2.9 |

3.45 |

4 |

4.6 |

5.75 |

6.75 |

7.75 |

|

|

dw |

min |

2 |

2.1 |

2.1 |

2.4 |

3.2 |

4.1 |

4.5 |

5 |

5.8 |

6.8 |

8.8 |

9.5 |

|

e |

min |

2.71 |

3.28 |

3.28 |

3.41 |

4.32 |

5.45 |

6.01 |

6.58 |

7.66 |

8.79 |

11.05 |

12.12 |

|

m′ |

max= nominal size |

0.8 |

1 |

1.2 |

1.3 |

1.6 |

2 |

2.4 |

2.8 |

3.2 |

4 |

5 |

5.5 |

|

min |

0.55 |

0.75 |

0.95 |

1.05 |

1.35 |

1.75 |

2.15 |

2.55 |

2.9 |

3.7 |

4.7 |

5.2 |

|

|

m |

min |

0.44 |

0.6 |

0.76 |

0.84 |

1.08 |

1.4 |

1.72 |

2.04 |

2.32 |

2.96 |

3.76 |

4.16 |

|

s |

max= nominal size |

2.5 |

3 |

3 |

3.2 |

4 |

5 |

5.5 |

6 |

7 |

8 |

10 |

11 |

|

min |

2.4 |

2. 9 |

2. 9 |

3.02 |

3.82 |

4.82 |

5.32 |

5.82 |

6.78 |

7.78 |

9.78 |

10.73 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

0.03 |

0.054 |

0.063 |

0.076 |

0.142 |

0.28 |

0.384 |

0.514 |

0.81 |

1.23 |

2.5 |

3.12 |

|

|

Specification-d |

M8 |

M10 |

M12 |

M14 |

M16 |

M18 |

M20 |

|

|

M8×1 |

M10×1 |

M12×1.5 |

M14×1.5 |

M16×1.5 |

M18×1.5 |

M20×2 |

||

|

|

M10×1.25 |

M12×1.25 |

|

|

M18×2 |

M20×1.5 |

||

|

P |

1.25 |

1.5 |

1.75 |

2 |

2 |

2.5 |

2.5 |

|

|

da |

min |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

max |

8.75 |

10.8 |

13 |

15.1 |

17.3 |

19.5 |

21.6 |

|

|

dw |

min |

11.3 |

15.3 |

17.2 |

20.2 |

22.2 |

25.3 |

28.2 |

|

e |

min |

14.38 |

18.9 |

21.1 |

24.49 |

26.75 |

29.56 |

32.95 |

|

m′ |

max= nominal size |

6.5 |

8 |

10 |

11 |

13 |

15 |

16 |

|

min |

6.14 |

7.64 |

9.64 |

10.3 |

12.3 |

14.3 |

14.9 |

|

|

m |

min |

4.91 |

6.11 |

7.71 |

8.24 |

9.84 |

11.44 |

11.92 |

|

s |

max= nominal size |

13 |

17 |

19 |

22 |

24 |

27 |

30 |

|

min |

12.73 |

16.73 |

18.67 |

21.67 |

23.67 |

26.16 |

29.16 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

5.2 |

11.6 |

17.3 |

25 |

33.3 |

49.4 |

64.4 |

|

|

Specification-d |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

M39 |

|

|

M22×1.5 |

M24×2 |

M27×2 |

M30×2 |

M33×2 |

M36×3 |

M39×3 |

||

|

M22×2 |

|

|

|

|

|

|

||

|

P |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

4 |

|

|

da |

min |

22 |

24 |

27 |

30 |

33 |

36 |

39 |

|

max |

23.7 |

25.9 |

29.1 |

32.4 |

35.6 |

38.9 |

42.1 |

|

|

dw |

min |

29.5 |

33.2 |

38 |

42.7 |

46.6 |

51.1 |

55.9 |

|

e |

min |

35.03 |

39.55 |

45.2 |

50.85 |

55.37 |

60.79 |

66.44 |

|

m′ |

max= nominal size |

18 |

19 |

22 |

24 |

26 |

29 |

31 |

|

min |

16.9 |

17.7 |

20.7 |

22.7 |

24.7 |

27.4 |

29.4 |

|

|

m |

min |

13.52 |

14.16 |

16.56 |

18.16 |

19.76 |

21.92 |

23.52 |

|

s |

max= nominal size |

32 |

36 |

41 |

46 |

50 |

55 |

60 |

|

min |

31 |

35 |

40 |

45 |

49 |

53.8 |

58.8 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

79 |

110 |

165 |

223 |

288 |

393 |

502 |

|

|

Specification-d |

M42 |

M45 |

M48 |

M52 |

M56 |

M60 |

M64 |

|

|

M42×3 |

M45×3 |

M48×3 |

M52×3 |

M56×4 |

M60×4 |

M64×4 |

||

|

P |

4.5 |

4.5 |

5 |

5 |

5.5 |

5.5 |

6 |

|

|

da |

min |

42 |

45 |

48 |

52 |

56 |

60 |

64 |

|

max |

45.4 |

48.6 |

51.8 |

56.2 |

60.5 |

64.8 |

69.1 |

|

|

dw |

min |

60.6 |

64.7 |

69.4 |

74.2 |

78.7 |

83.4 |

88.2 |

|

e |

min |

71.3 |

76.95 |

82.6 |

88.25 |

93.56 |

99.21 |

104.86 |

|

m′ |

max= nominal size |

34 |

36 |

38 |

42 |

45 |

48 |

51 |

|

min |

32.4 |

34.2 |

36.4 |

40.4 |

43.4 |

46.4 |

49.4 |

|

|

m |

min |

25.9 |

27.5 |

29.1 |

32.3 |

34.7 |

37.1 |

39.3 |

|

s |

max= nominal size |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

|

min |

63.1 |

68.1 |

73.1 |

78.1 |

82.8 |

87.8 |

92.8 |

|

|

Weight (7.85kg/dm) ≈kg thousand pieces |

652 |

800 |

977 |

1220 |

1420 |

1690 |

1980 |

|

FAQ:

Q1: What is a 2507 Hex Nut?

A: A 2507 Hex Nut is a DIN 934 hexagonal nut made from super duplex stainless steel 2507, designed for extreme strength and corrosion resistance.

Q2: What is the difference between 2205 and 2507 stainless steel nuts?

A: While both are duplex steels, the 2507 "Super Duplex" grade offers significantly higher yield strength (800-1000 MPa) and enhanced resistance to chloride pitting compared to the 2205 grade.

Q3: Why should I use a DIN 934 standard nut?

A: The DIN 934 standard ensures that the nut meets specific international dimensions and thread pitches. This guarantees that your 2507 Hex Nut will fit perfectly with any corresponding metric bolt or threaded rod.

Q4: Is the 2507 Hex Nut suitable for offshore oil and gas applications?

A: Yes. Due to its superior resistance to seawater and stress corrosion, it is specifically designed for the most aggressive environments, including offshore platforms and subsea equipment.

Q5: Will these nuts slip under high vibration?

A: No. The combination of the precise hexagonal shape and deep-cut threads ensures the nut locks tightly and maintains uniform force distribution to prevent loosening.