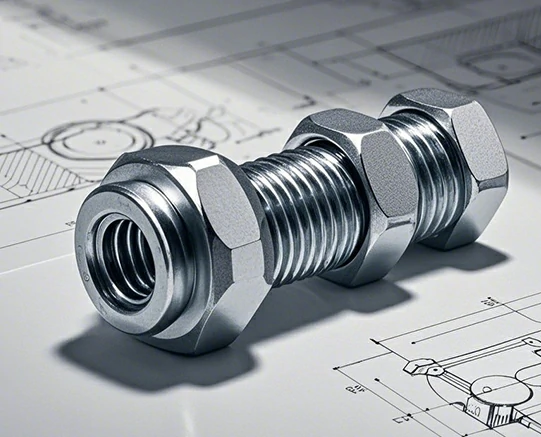

We offer a seamless process for designing and manufacturing custom fasteners. Our team works closely with you to understand the exact specifications and needs of your project. Whether you require stainless steel fasteners or other specialized materials, we ensure the design captures every detail.

At Tianqi Fasteners, we prioritize quality control throughout the entire production process. Our professional quality management team conducts rigorous testing and inspections on all our stainless steel fasteners to guarantee their reliability and performance.

Performance Testing: Ensures that each custom fastener meets the required strength, durability, and functionality for your specific application.

Durability Testing: We simulate real-world conditions to assess the long-term reliability of your OEM fasteners.

As a trusted fasteners manufacturer, we offer custom fasteners made from high-quality, durable stainless steel that meet demanding specifications.

Our team is equipped to create OEM fasteners based on your unique design requirements, ensuring a perfect fit for any application.

Each stainless steel fastener undergoes strict testing to guarantee performance, longevity, and reliability.

With efficient processes in place, we deliver custom fasteners on time without compromising on quality.