Description

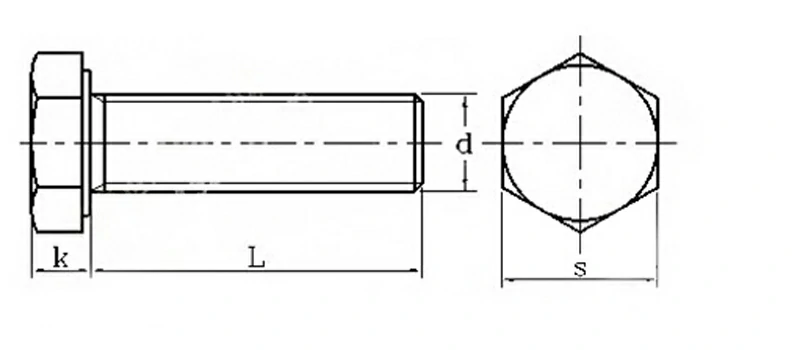

The 316L Stainless Steel DIN 933 Hex Bolt (A4-80) is a fully threaded, high-performance fastener engineered for applications requiring superior mechanical strength and exceptional corrosion resistance. Manufactured from low-carbon 316L stainless steel, this hexagonal head bolt is specifically designed to withstand aggressive environments such as marine, offshore, chemical processing, wastewater systems, and other corrosive industrial locations. Meeting the international DIN 933 standard, this bolt features full threading along the shank for maximum engagement, providing secure and reliable fastening for structural, mechanical, and assembly applications. With its A4-80 strength class, it delivers an impressive tensile strength of 800 N/mm², making it suitable for demanding load-bearing tasks where reliability is crucial.

Features & Benefits

- Exceptional Strength: The A4-80 strength class provides a tensile strength of 800 N/mm², offering reliable performance in high-stress and demanding applications.

- Superior Corrosion Resistance: Made from 316L stainless steel, this bolt offers outstanding resistance to wear, oxidation, and corrosion, particularly in environments exposed to chlorides, saltwater, and harsh chemicals.

- Full Thread Design: The fully threaded shank (as per DIN933 standard) ensures maximum engagement with a nut or threaded hole, providing a strong and secure connection.

- Durable & Practical: Boasts high hardness and is resistant to rust and deformation, ensuring a long service life and reliable performance in humid or corrosive settings.

Specification

|

Specification (d) |

M4 |

M5 |

M6 |

M8 |

M10 |

M12 |

M14 |

M16 |

|

Pitch |

0.7 |

0.8 |

1 |

1.25 |

1.5 |

1.75 |

2 |

2 |

|

Opposite side (s) |

7 |

8 |

10 |

13 |

17 |

19 |

22 |

24 |

|

Head thickness (k) |

2.8 |

3.4 |

4.1 |

5.3 |

6.8 |

7.5 |

9 |

10 |

|

Specification (d) |

M18 |

M20 |

M22 |

M24 |

M27 |

M30 |

M33 |

M36 |

|

Pitch |

2.5 |

2.5 |

2.5 |

3 |

3 |

3.5 |

3.5 |

4 |

|

Opposite side (s) |

27 |

30 |

32 |

36 |

41 |

46 |

50 |

55 |

|

Head thickness (k) |

12 |

12.5 |

14 |

15 |

17 |

19 |

21 |

23 |

FAQs:

Q1: What is the difference between DIN 933 and DIN 931?

A: The DIN 933 standard specifies that the hexagonal head bolt must be fully threaded (threads run all the way up to the bolt head). This contrasts with the DIN 931 standard, which specifies a partially threaded shank.

Q2: Is 316L stainless steel better than 304 for corrosion resistance?

A: Yes. 316L contains molybdenum, providing significantly better resistance to chlorides, saltwater, and acidic environments compared to 304 stainless steel.

Q3: What is the main difference between A4-70 and A4-80 bolts?

A: Both are made from 316 stainless steel (A4). The difference is strength: A4-70 has a minimum tensile strength of 700 N/mm², while the A4-80 is a higher strength grade with a minimum tensile strength of 800 N/mm², making it suitable for applications requiring greater mechanical load capacity.

Q4. Can this bolt be used outdoors or in marine environments?

A: Absolutely. 316L stainless steel is one of the best materials for saltwater, moisture, and chemical resistance.